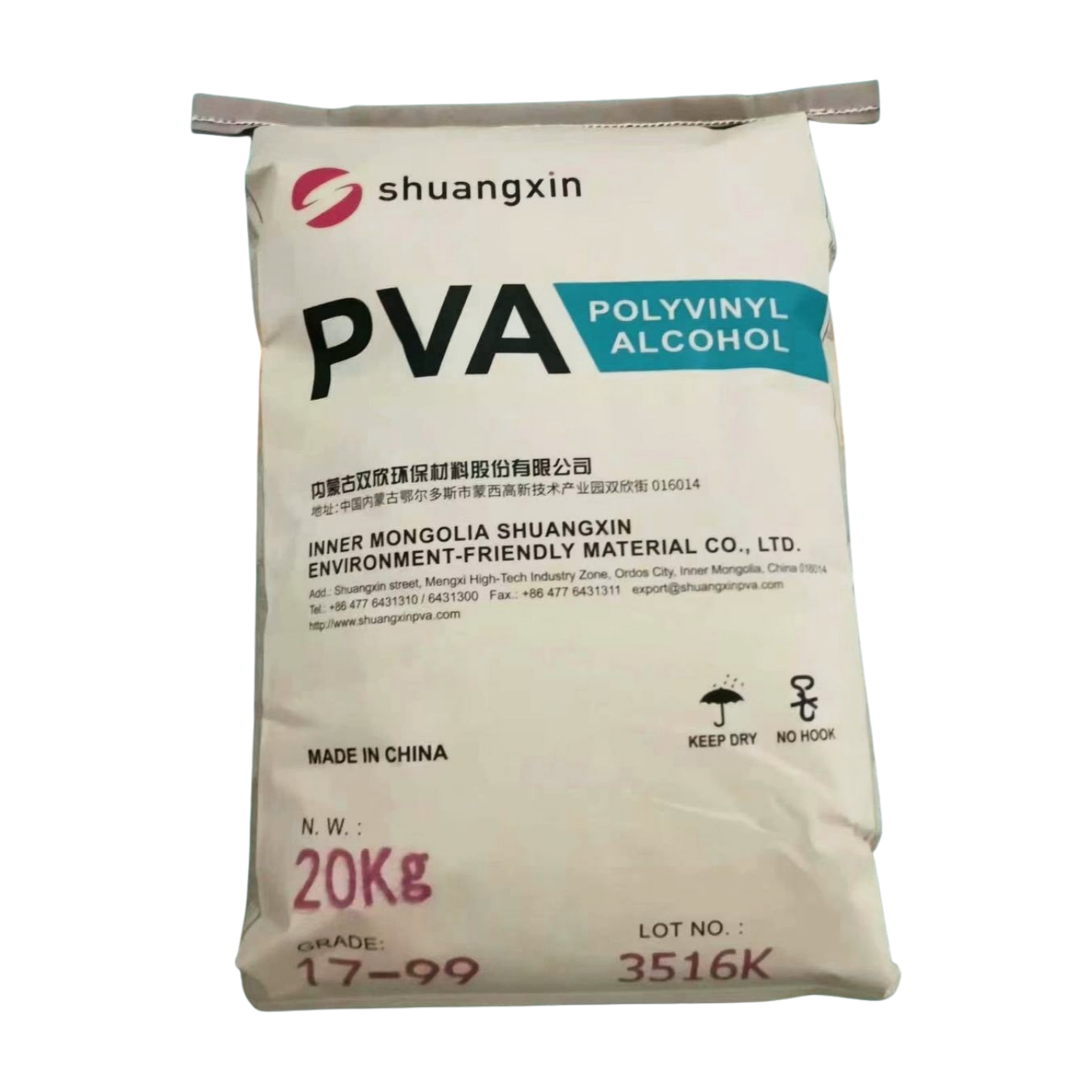

PVA’s water solubility depends on hydrolysis degree (DH) and molecular weight (MW). Fully hydrolyzed PVA (DH ≥98%) requires heating to 80-90°C for dissolution, forming clear, viscous solutions, while partially hydrolyzed grades (DH 87-89%) dissolve in cold water. Low-MW PVA (13-23k Da) dissolves faster than high-MW (85-124k Da) due to reduced chain entanglement. Particle size matters: fine powders dissolve quicker than coarse granules. Solubility peaks at 60°C, with modern formulations achieving 99.7% dissolution in 15 minutes at 70°C. Overheating may cause gelation. Typically, PVA reaches 5-20% w/v solubility, with higher concentrations increasing viscosity. For example, PVA 2488 (DH 98-99%, MW ~140k Da) dissolves at 95°C, forming strong films, while PVA 1788 (DH 87-89%, MW ~140k Da) dissolves at 20°C, ideal for cold-process applications.