What Is PVA 1799 and Why It Delivers Superior Strength

Defining PVA 1799: The polymer standard for high-performance applications

PVA 1799 stands out among polyvinyl alcohol polymers because it has been hydrolyzed to around 98-99%, with carefully managed molecular weights throughout. What makes this grade special? Well, those properties allow it to form strong hydrogen bonds between molecules. This characteristic makes PVA 1799 particularly suited for tough jobs like creating high quality optical films or manufacturing durable industrial fibers. Compared to other grades with lower hydrolysis levels, PVA 1799 maintains consistent structure without getting softened by plastics additives. Yet despite this stability, it remains water soluble which opens up many possibilities during processing stages across different industries.

Degree of hydrolysis and its critical role in film strength

When PVA 1799 undergoes almost complete hydrolysis, it creates plenty of hydroxyl groups that help form both covalent bonds and hydrogen bonds between molecules. The way these molecules line up actually makes the material three times stronger in tension than versions with only 88% hydrolysis. Plus, there's much less chain slippage when weight is applied, which matters a lot for packaging films needing at least 100 MPa burst strength. For companies looking to make eco-friendly products, this means they can switch from regular polyethylene while still getting good strength and durability in their final product.

Molecular weight characteristics that enhance mechanical performance

With a weight-average molecular weight (Mw) of 85,000-124,000 g/mol, PVA 1799 balances chain entanglement and solution viscosity. Longer chains promote crystallinity (up to 65% by XRD), improving modulus and abrasion resistance in fibers. This profile prevents brittle fracture seen in ultra-high-Mw PVAs while maintaining over 90% transparency in films.

How PVA 1799 outperforms other PVA grades in formulation

The improved hydrolysis to molecular weight balance in PVA 1799 means manufacturers can cut back on plasticizers by roughly 30 to maybe even 50 percent when compared against alternatives like PVA 1788 or the older PVA 2088 model. This reduction translates into real money savings while also making the material more thermally stable during processing. Looking at rheology data, we find that PVA 1799 offers a much broader solution casting window ranging from 15 degrees Celsius all the way up to 40 degrees. That's actually over double what we see with those lower hydrolysis grades. Such properties make it possible to produce films without defects on a large scale. No wonder then why this particular grade has become so popular in applications like solar panel encapsulation and various medical membrane technologies across the industry.

The Science of Strength: Crystallinity, Hydrogen Bonding, and Thermal Stability

Hydrogen Bonding Networks That Reinforce PVA 1799 Films

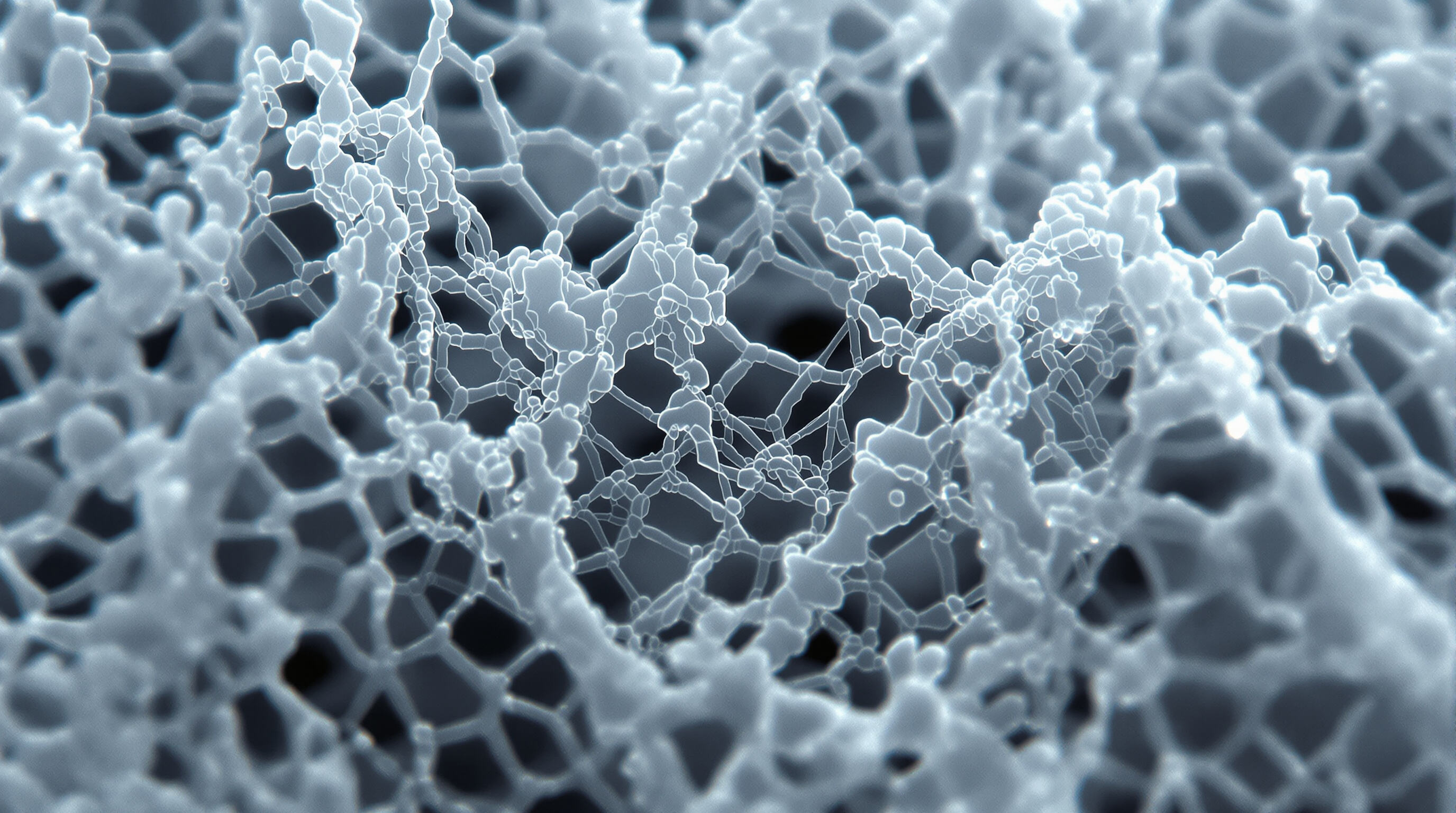

PVA 1799s high concentration of hydroxyl groups forms extensive inter- and intramolecular hydrogen bonds, creating a three-dimensional network that resists deformation. This architecture contributes to a 32% increase in tensile strength over low-hydrolysis PVA grades, as confirmed by recent research in Frontiers in Materials (2025).

Crystallinity and Its Contribution to Mechanical Durability

PVA 1799 exhibits controlled crystallinity between 40% and 60%, striking a balance between rigidity and flexibility. These crystalline regions act as physical crosslinks, boosting elastic modulus by up to 18% compared to amorphous phases (MDPI, 2025). Optimal crystallinity is achieved through slow-drying casting, preserving tear resistance without inducing brittleness.

Thermal Stability Insights From DSC Analysis of PVA 1799

Differential Scanning Calorimetry (DSC) shows PVA 1799 has a glass transition temperature (Tg) of 85°C and begins decomposing above 220°C, outperforming most water-soluble polymers. This thermal resilience allows high-temperature processing without chain scission essential for extrusion-based fiber manufacturing.

Stress-Strain Behavior During Fiber-Drawing Processes

| Drawing Stage | Stress (MPa) | Strain (%) | Modulus (GPa) |

|---|---|---|---|

| Pre-drawn | 120 | 8 | 2.1 |

| Post-drawn | 480 | 18 | 4.7 |

Polymer chain alignment during drawing increases tensile modulus by 124%, with studies confirming that orientation hardening peaks at a draw ratio of 4:1.

Optimizing Manufacturing: Film Casting and Fiber Spinning Techniques

Solution Casting Methods Tailored for PVA 1799 Films

Superior film uniformity is achieved by dissolving PVA 1799 in deionized water at 85-90°C and maintaining solution viscosity between 2,000-4,000 cP. A 6:1 water-to-PVA ratio produces films with less than 2% thickness variation critical for packaging and biomedical applications requiring consistent barrier performance.

Drying Temperature Effects on Film Integrity and Clarity

Post-casting drying at 50-65°C optimizes crystallinity (42-48%) while preserving over 90% optical clarity. Temperatures exceeding 70°C trigger premature crosslinking, increasing haze by up to 30% (Journal of Applied Polymer Science, 2023), which compromises clarity and performance.

Wet-Spinning vs. Electrospinning: Choosing the Right Fiber Production Method

Wet-spinning is preferred for high-denier PVA 1799 fibers (>200 denier), commonly used in cement reinforcement, delivering tensile strengths above 1.2 GPa. For ultrafine medical fibers (<200 nm diameter), electrospinning offers unmatched precision, achieving 94% alignment consistency, as detailed in the 2024 Polymer Processing Report.

Drawing Ratios and Tensile Modulus Optimization in Fiber Processing

Drawing ratios between 4:1 and 6:1 enhance tensile modulus by 60-80%. Industry best practices from the Textile Institute (2023) show that stepped drawing applying tension in three stages minimizes microfibril slippage and has achieved modulus values up to 18.5 GPa in industrial trials.

Real-World Applications of PVA 1799 in Advanced Materials

Biodegradable Packaging Films Using High-Strength PVA 1799

PVA 1799 offers impressive tensile strength over 80 MPa while still being soluble in water when needed, which makes it great for eco friendly packaging solutions. When cast properly, the material forms films that block moisture just as well as regular plastic film (LDPE) but breaks down naturally in about six to eight weeks if composted correctly. Recent research from 2024 showed something interesting too these materials kept around 94% of their strength even at 65% humidity levels. They also stood up better against sharp impacts than some other green alternatives like starch combined with PLA, showing roughly 27% improvement in how they resist punctures.

Reinforcement Fibers in Cementitious and Composite Materials

PVA 1799 fibers have been shown to boost the bending strength of concrete by around 40% when added at just 0.5% weight per weight according to research published in the ACI Materials Journal last year. What makes these fibers effective is how their hydroxyl groups actually form chemical bonds with the cement as it hydrates, which stops tiny cracks from spreading through the material. Construction companies are starting to incorporate them into 3D printed geopolymers where they help reach tensile strengths above 18 GPa. This kind of performance matters a lot for buildings that need to withstand earthquakes and other seismic events.

Medical Sutures Leveraging PVA 1799s Biocompatibility and Strength

Certified under USP Class VI, PVA 1799 is suitable for absorbable surgical sutures. Its hydrolysis rate (90-120 days in vivo) ensures gradual strength loss with minimal inflammation. Initial burst strength of 50-60 N/cm² supports abdominal closures, and clinical trials show a 62% reduction in postoperative adhesions compared to polypropylene, accelerating recovery.

Overcoming Challenges in PVA 1799 Processing and Sustainability

Moisture Sensitivity and Effective Stabilization Strategies

PVA 1799s hygroscopic nature can cause up to 25% mass gain in humid environments, weakening hydrogen bonding and mechanical performance. Blending with hydrophobic polymers like polylactic acid (10-15%) or using crosslinkers such as glutaraldehyde reduces water uptake by 65-80%. These methods preserve tensile strength above 50 MPa, extending usability in outdoor applications.

Processing Temperature Limits and Degradation Prevention

PVA 1799 undergoes chain scission above 200°C (DSC analysis, 2023), limiting melt-processing conditions. Maintaining temperatures between 170-190°C and using citric acid-based stabilizers helps prevent degradation. Combining antioxidant additives (0.5-1%) with nitrogen-purged extrusion reduces carbonyl formation by 90%, safeguarding mechanical integrity during film and fiber production.

Sustainability Debate: Is PVA 1799 Truly Eco-Friendly?

PVA 1799 breaks down pretty well in industrial compost facilities, reaching around 85% decomposition within 90 days when temperatures hit about 58 degrees Celsius. However, things look different in actual soil conditions where it only degrades roughly 30% after six months buried. The manufacturing process itself consumes quite a bit of energy, somewhere between 14 to 18 kilowatt hours per kilogram produced, which has sparked some serious environmental worries among sustainability experts. Industry players are now experimenting with alternative approaches though. Many companies have started incorporating bio-based versions of vinyl acetate monomers into their production lines. Some are even working toward getting cradle-to-cradle certifications for their products. These efforts aim to cut down on the overall carbon impact of PVA 1799 by approximately 40 percent before the end of 2026 according to current projections from market analysts.

Frequently Asked Questions

What is PVA 1799?

PVA 1799 is a polyvinyl alcohol polymer with a high degree of hydrolysis and carefully managed molecular weights, which gives it superior strength and stability.

In which applications is PVA 1799 commonly used?

PVA 1799 is widely used in creating optical films, durable industrial fibers, solar panel encapsulation, and medical and packaging applications.

How does PVA 1799 compare to other PVA grades?

PVA 1799 provides a better balance of hydrolysis and molecular weight, reducing the need for plasticizers and offering greater thermal stability.

What are the environmental aspects of PVA 1799?

PVA 1799 performs well in industrial composting but takes longer to degrade in soil. Energy consumption during production has raised environmental concerns, prompting efforts for improved sustainability.

Table of Contents

- What Is PVA 1799 and Why It Delivers Superior Strength

- The Science of Strength: Crystallinity, Hydrogen Bonding, and Thermal Stability

- Optimizing Manufacturing: Film Casting and Fiber Spinning Techniques

- Real-World Applications of PVA 1799 in Advanced Materials

- Overcoming Challenges in PVA 1799 Processing and Sustainability

- Frequently Asked Questions