Understanding Redispersible Polymer Powder (RDP) and Its Role in Crack Resistance

What is redispersible polymer powder (RDP) and how it functions in mortar

Redispersible polymer powder, often called RDP for short, starts life as a spray dried polymer emulsion. When we add it to water, it turns back into something flexible and sticky that gets incorporated into mortar mixtures. Most RDP products contain copolymers like vinyl acetate ethylene (VAE) which acts kind of like glue between the cement particles and whatever surface they're being applied to. This connection makes the whole mixture stick together better without becoming so brittle that it breaks easily. The way it works is pretty interesting actually. Once mixed into the mortar, these tiny polymer particles spread out evenly throughout the mix. As the mortar dries, the polymers start to link up with each other, creating a sort of web inside the material. This internal network helps soak up stresses from different directions and spreads out the forces instead of letting them concentrate in one spot. What this means practically speaking is fewer cracks forming when the mortar dries too fast or experiences temperature fluctuations over time.

Enhancing flexibility and tensile strength through RDP modification

When we modify mortar with RDP, it actually cuts down on the elastic modulus by around 40%. What does this mean? Well, the material becomes flexible enough to move along with whatever surface it's applied to without developing cracks. Tests show that the new polymer matrix boosts tensile strength somewhere between 25% and 30% over regular mortar. Standard flexural tests back this up, though results can vary depending on how the samples were prepared. For things like exterior insulation systems, this balance between being able to bend and still holding strong matters a lot. These systems face constant challenges from wind pushing against them and all those daily temperature changes that expand and contract materials throughout the day.

Polymer film formation and its role in reducing crack propagation

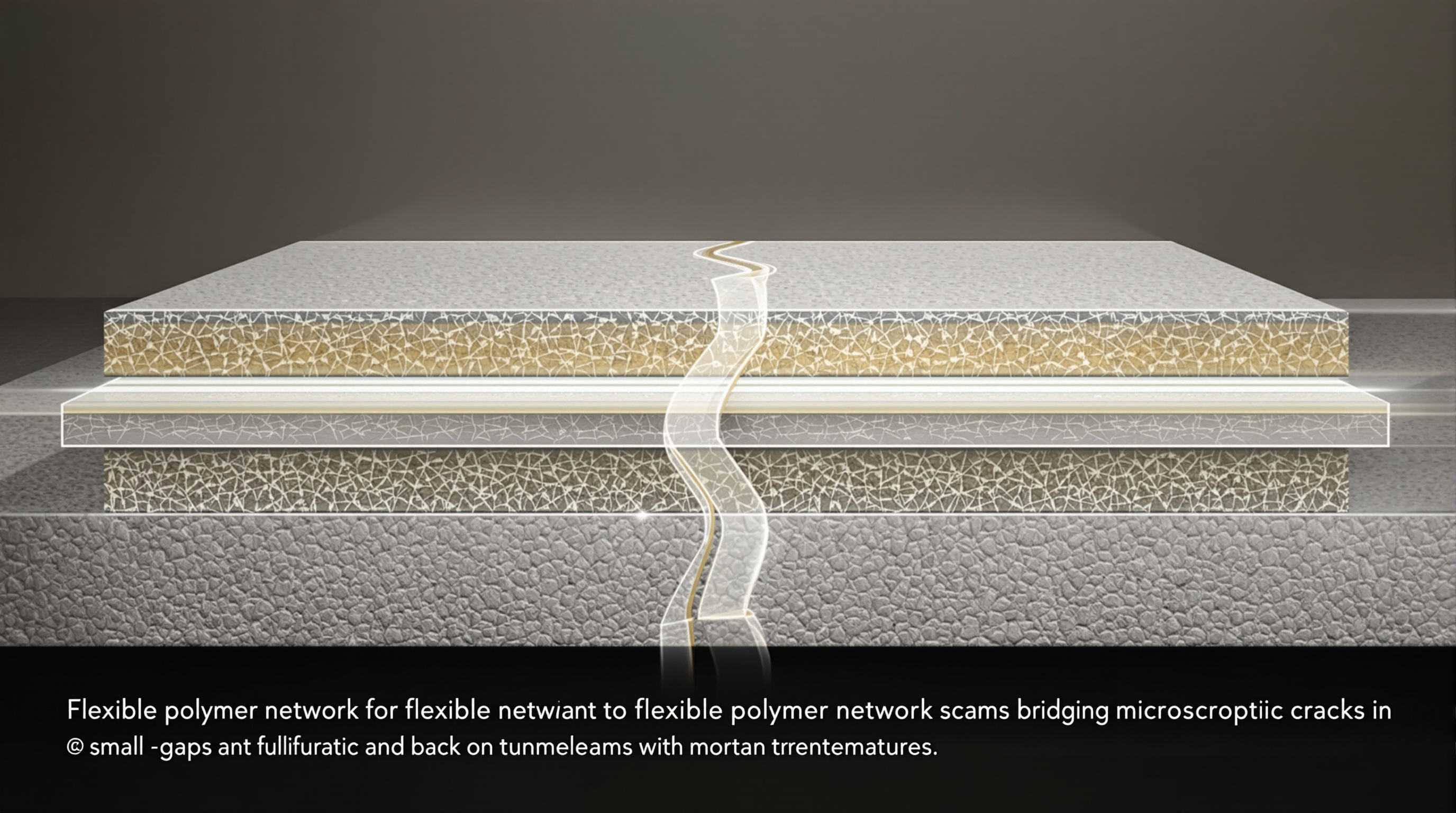

When mortar starts to dry out, RDP creates this kind of continuous polymer film that actually goes into those tiny capillary pores and sticks to the cement hydrates. What makes this film so useful is how it works as sort of a barrier against cracks. Instead of letting small cracks spread quickly, the film spreads out the stress over its whole network. For VAE based RDP specifically, these films have some real flexibility too stretching about 150% before breaking. That means they can literally span across emerging cracks in the material and stop them from becoming actual visible fractures down the road.

Reducing elastic modulus to accommodate substrate movement

By lowering stiffness, RDP allows mortar to tolerate structural shifts from thermal expansion—up to 2 mm/m in concrete—without delamination. This property is especially important in earthquake-prone areas, where building codes require mortars to maintain adhesion under cyclic loading.

The Importance of Vinyl Acetate-Ethylene (VAE) in RDP Formulations

Why VAE is a preferred copolymer in high-performance RDP

VAE or Vinyl Acetate-Ethylene stands out as the top choice among redispersible polymer powders because it hits that sweet spot between being elastic enough, affordable, and working well with cement-based materials. What makes this material special is how it brings together ethylene's stretchiness with the strong sticking power of vinyl acetate. This combination works great in mortar mixes that need to handle temperature changes and all sorts of stress over time. Looking at what's happening in the industry right now, we see why VAE keeps dominating construction grade RDP formulas. Stricter rules about volatile organic compounds plus higher expectations for performance have pushed manufacturers toward this option. Plus, when creating products like tile adhesives or insulation systems for outside walls, formulators can hit those tough ISO standards for bonding strength while still keeping the mix easy to work with on site.

How VAE enhances elasticity, adhesion, and durability of polymer films

When VAE is added to RDP, it forms these intricate polymer networks that actually span across tiny cracks in the mortar while keeping the overall structure intact. The ethylene parts work kind of like tiny shock absorbers at the molecular level, which cuts down on how stiff the material becomes. We're talking about around a 40% drop in stiffness compared to regular binders. This makes all the difference when dealing with substrates that move just a little bit over time. Mortar mixed this way can cope with movements between 2 and 3 millimeters per meter before breaking down something that matters a lot for big tiles installed across large areas. On the other side of things, those vinyl acetate bits get really good at bonding with the cement as it hydrates. The result? Pull off strengths well above 1.5 Newtons per square millimeter even on tricky surfaces such as old painted concrete where traditional methods often struggle.

Key properties of VAE that improve mortar performance under stress

Three core characteristics make VAE essential for crack prevention:

- Thermal Stability: Maintains flexibility from -20°C to 90°C

- Hydrophobic Backbone: Reduces water absorption by 60–70% versus unmodified mortar

- Stress Distribution: Polymer films spread point loads over areas 5–10x larger

Together, these properties enable VAE-based RDP to meet EN 12004 standards for deformable adhesives and extend service life in freeze-thaw environments. Field data indicate structures using VAE-modified mortars require 35% fewer repairs over a decade compared to traditional mixes.

Mechanisms by Which RDP and VAE Prevent Mortar Cracking

Stress dispersion and crack bridging through polymer network formation

When RDP gets combined with VAE, it creates this sort of flexible 3D polymer network inside the mortar mixture. What happens then is that this network spreads out mechanical forces across the whole material instead of letting them build up at weak spots. Microcracks start forming? No problem really because those VAE boosted polymer fibers actually span across these tiny cracks. Tests have indicated somewhere around a 50-60% reduction in how fast these cracks spread when exposed to freezing and thawing cycles. These elastic film layers stick together even as the base material expands and contracts, something that matters a lot for materials used outside where temperatures fluctuate constantly throughout the day and seasons.

Improved bond strength between mortar and substrate using RDP/VAE systems

When RDP works together with VAE, it actually makes the bond between mortar and whatever surface it's applied to much stronger through two different ways. The VAE has these polar groups that form chemical bonds with minerals found in most building materials. At the same time, the RDP particles get lodged into tiny holes and crevices in the substrate surface. Tests show this combination can boost bonding strength anywhere from 25 to 35 percent compared to regular mortars, especially important for tricky surfaces like old weathered concrete or ceramic tiles that tend to be harder to stick to. What's really useful is how this modified layer stays flexible even when stressed, so it doesn't crack and peel off like traditional rigid mortars do when buildings settle or shift just a little bit over time.

Optimizing RDP with VAE for Performance and Cost Efficiency

Recommended Dosage Ranges of VAE-Based RDP for Maximum Crack Resistance

When it comes to VAE modified RDP in cement based mortars, the sweet spot generally falls between 1% and 5% by weight, though what works best really depends on specific project requirements. Take exterior insulation systems exposed to temperature fluctuations for instance – most experts suggest aiming for around 3.2% to 4.1% VAE RDP content. This range typically results in about an 85% reduction in cracking issues while still keeping compressive strength well above the critical 25 MPa threshold. Going overboard with more than 5% actually starts causing problems like poor workability and significantly higher material costs, often jumping up between 18% and 22%. On the flip side, using less than 1% isn't wise either since this leaves the mortar vulnerable to shrinkage cracks, especially when dealing with substrates that move more than 2 mm per meter during expansion or contraction cycles.

Balancing Formulation Cost and Technical Performance in Real-World Applications

A dosage of 2.5–3.5% VAE-RDP offers the best balance, reducing crack-related repair costs by 34% over five years compared to unmodified mortars. This range improves:

- Water resistance (≤ 0.5% absorption after 72 hours)

- Flexural strength retention (92% after 50 freeze-thaw cycles)

- Adhesion to porous substrates (>1.5 N/mm²)

While acrylic-based polymers provide 12–15% higher elasticity, VAE-RDP delivers 30% better cost efficiency for residential projects requiring moderate deformation tolerance (≤1.8 mm/m).

Frequently Asked Questions

What is Redispersible Polymer Powder (RDP)?

RDP, or Redispersible Polymer Powder, is a spray-dried polymer emulsion that, when mixed with water, reverts to a flexible and sticky state, improving the properties of mortars in construction.

How does RDP improve crack resistance in mortars?

RDP enhances crack resistance by forming a web-like network inside the mortar, distributing stress and reducing the formation of cracks due to fast drying or temperature changes.

Why is Vinyl Acetate-Ethylene (VAE) important in RDP?

VAE is a preferred copolymer in RDP due to its elasticity, affordability, and compatibility with cement-based materials, enhancing flexibility, adhesion, and durability of polymer films.

What are the optimal dosage ranges for VAE-based RDP?

The optimal dosage generally falls between 1% to 5% by weight, with 2.5% to 3.5% balancing cost and performance efficiently, depending on specific project needs.

How does VAE improve mortar performance under stress?

VAE improves performance by maintaining thermal stability, reducing water absorption, and distributing stress, which helps meet building standards and reduces repair needs over time.