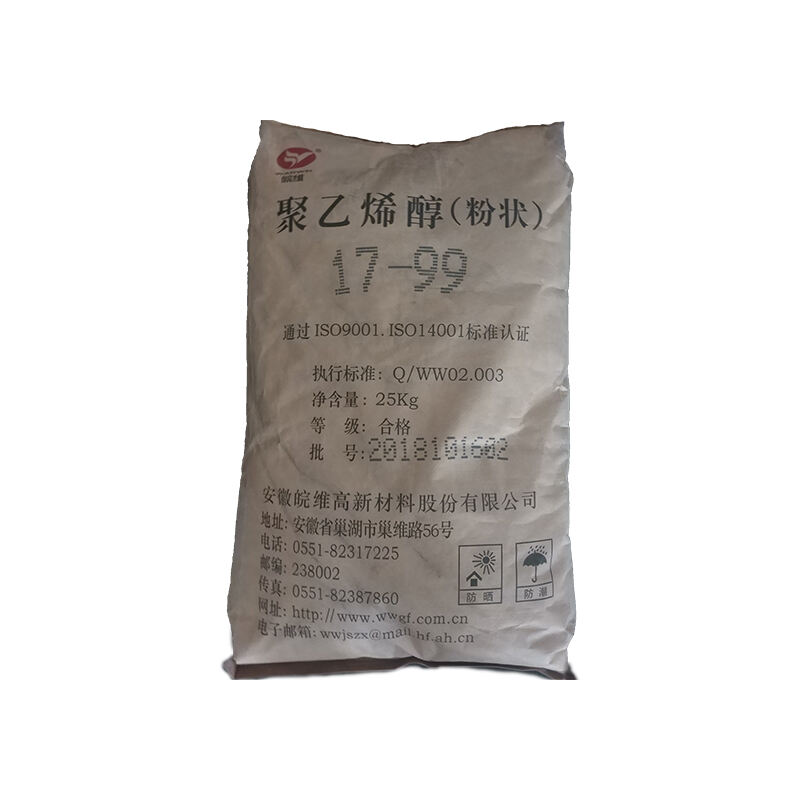

Wanwei PVA 17-99 (L) & PVA 100-27(BF-17 & PVA 117 & PVOH 28-98)

Description

Overview

The appearance of PVA is white flake, granular or powdery solid (low-alkali alcoholysis process) or white flocculent solid (high-alkali alcoholysis process). It is a kind of water-soluble polymer with wide application, and its performance is between plastic and rubber. It has unique strong adhesion, film flexibility, oil resistance, surface activity, gas barrier, wear resistance and so on.

Technical Data

Item |

Hydrolysis (mol%) |

Viscosity (mpa.s) |

Volatile (%≤) |

Ash (%≤) |

PH (Value) |

Purity (% ≥) |

17-99(L) |

99.0-100.0 |

22.0-32.0 |

≤7.0 |

≤0.5 |

5~7 |

≥93.5 |

17-99(H) |

99.0-100.0 |

20.0-26.0 |

≤8.0 |

≤2.8 |

7~10 |

≥93.5 |

Product Application

Fabric Sizing Material

Polyvinyl alcohol in fabric sizing materials becomes a core auxiliary agent for improving weaving efficiency through the triple mechanism of "film protection-hydrogen bond adhesion-surface smoothing". It has the advantages of significantly reducing the breakage rate, improving the quality of the fabric, and combining environmental protection with easy operation.

Adhesive

Polyvinyl alcohol in adhesives has become a multi-scenario bonding solution through the three-in-one mechanism of "polar adhesion-film enhancement-chemical modification". Its core value lies in safety and environmental protection, broad-spectrum bonding, and easy modification, and it is especially suitable for cellulose substrates.

PVA Film

As the core raw material of PVA film, polyvinyl alcohol has shown significant advantages in packaging, medical treatment, agriculture and other fields due to its unique molecular structure and physical and chemical properties.

Coating

Polyvinyl alcohol has become a "performance bridge" in the coating system through the four mechanisms of film-forming reinforcement, interface bonding, construction optimization and functional modification. Its core value lies in the balance of rigidity and flexibility (improving the crack resistance and adhesion of the coating), water-air regulation (considering both waterproof and breathable requirements), and environmental protection and economy (non-toxic, biodegradable, and reducing the amount of emulsion). The selection needs to be combined with the application scenario.

Packages

12.5 kg/bag, 25 kg/bag.

Storage

Avoid generation or accumulation of dusts. Take precautionary measures against static discharges, earth/ground all equipment. Avoid contact with heated or molten product. Do not breathe dust, fumes or vapors from heated product. Use local exhaust ventilation in processing area. Take precautionary measures against direct sunlight and rain drenching during transport. Keep transportation vehicle clean. Avoid packaging destruction and keep away from impurity.