Wanwei PVA 05-99(L) & PVA 098-05

Description

Overview

The appearance of PVA is white flake, granular or powdery solid (low-alkali alcoholysis process) or white flocculent solid (high-alkali alcoholysis process). It is a kind of water-soluble polymer with wide application, and its performance is between plastic and rubber. It has unique strong adhesion, film flexibility, oil resistance, surface activity, gas barrier, wear resistance and so on.

Technical Data

Item |

Hydrolysis (mol%) |

Viscosity (mpa.s) |

Volatile (%≤) |

Ash (%≤) |

PH (Value) |

Purity (% ≥) |

05-99(L) |

98.0-99.8 |

4.5-7.0 |

≤7.0 |

≤0.7 |

5~7 |

≥93.5 |

Product Application

Warp Yarn Sizing

Polyvinyl alcohol is used as a sizing agent to enhance yarn strength and abrasion resistance, reduce yarn breakage rate during weaving, and improve textile quality.

Emulsifier

Polyvinyl alcohol plays a dual role as an interface stabilizer and a structural enhancer in emulsifiers. Its performance can be precisely controlled by the degree of alcoholysis, degree of polymerization and compounding strategy.

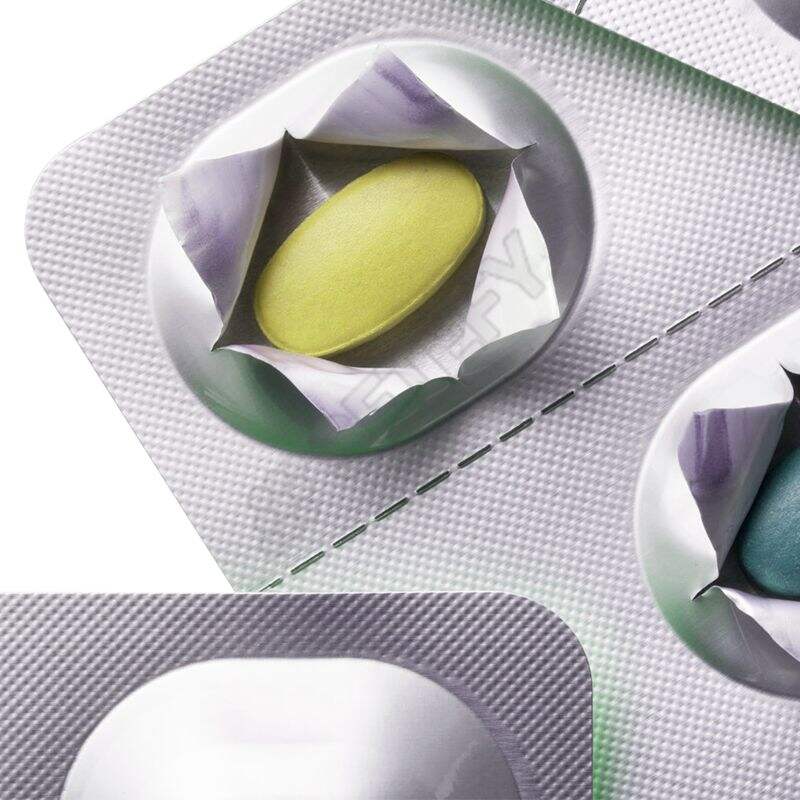

Medical Film

Polyvinyl alcohol can be used in drug film applications to wrap drugs, control the release rate, and prolong the therapeutic effect.

Release Agent

Polyvinyl alcohol acts as a physical isolation film in the release agent, blocking resin adhesion through water-soluble film formation, and is particularly suitable for new mold protection, complex structure demolding and environmental protection requirements. Its advantages are safe and clean, no transfer residue, but attention should be paid to temperature limits (≤150℃) and surface roughness control.

Package

25 kg/bag.

Storage

Avoid generation or accumulation of dusts. Take precautionary measures against static discharges, earth/ground all equipment. Avoid contact with heated or molten product. Do not breathe dust, fumes or vapors from heated product. Use local exhaust ventilation in processing area. Take precautionary measures against direct sunlight and rain drenching during transport. Keep transportation vehicle clean. Avoid packaging destruction and keep away from impurity.