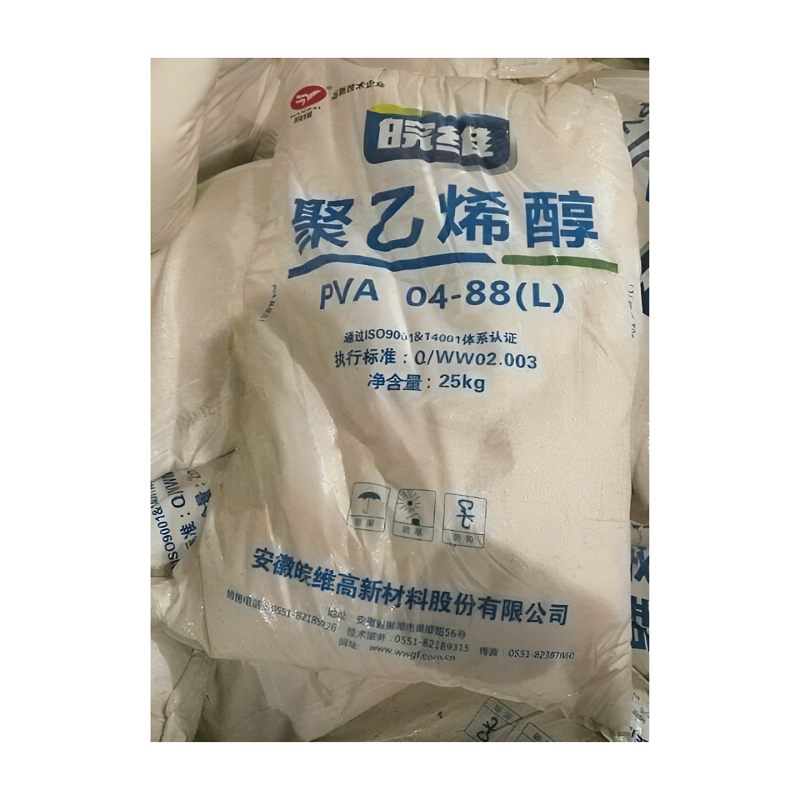

Wanwei PVA 04-88(L) & PVA 088-04

Description

Overview

The appearance of PVA is white flake, granular or powdery solid (low-alkali alcoholysis process) or white flocculent solid (high-alkali alcoholysis process). It is a kind of water-soluble polymer with wide application, and its performance is between plastic and rubber. It has unique strong adhesion, film flexibility, oil resistance, surface activity, gas barrier, wear resistance and so on.

Technical Data

Item |

Hydrolysis (mol%) |

Viscosity (mpa.s) |

Volatile (%≤) |

Ash (%≤) |

PH (Value) |

Purity (% ≥) |

04-88(L) |

85.0-90.0 |

3.5-4.5 |

≤7.0 |

≤0.7 |

5~7 |

≥93.5 |

Product Application

Water-soluble Film

Polyvinyl alcohol is used to produce water-soluble films, which dissolve in water and are environmentally friendly.

High-density Sizing Material

Polyvinyl alcohol plays a core role in high-density sizing materials and has the characteristics of enhancing yarn strength and wear resistance, optimizing the balance between sizing liquid penetration and coating, stabilizing the process and reducing environmental dependence.

Papermaking

In the papermaking industry, polyvinyl alcohol has become a multifunctional additive for improving paper performance through the three-in-one mechanism of "fiber reinforcement-surface film formation-adhesion optimization". Its core value lies in its balance of strength, water resistance and printability, and it is safe, non-toxic and biodegradable.

Emulsion

Polyvinyl alcohol is a multifunctional additive in emulsions: as an emulsifier, it promotes monomer dispersion; as a stabilizer, it maintains system uniformity; as a thickener, it adjusts rheological properties; and through film-forming effects, it improves film strength and adhesion. The selection of its alcoholysis degree and polymerization degree directly affects the water resistance, antifreeze and construction performance of the emulsion, and the formula needs to be optimized according to the specific application scenario.

Package

25 kg/bag.

Storage

Avoid generation or accumulation of dusts. Take precautionary measures against static discharges, earth/ground all equipment. Avoid contact with heated or molten product. Do not breathe dust, fumes or vapors from heated product. Use local exhaust ventilation in processing area. Take precautionary measures against direct sunlight and rain drenching during transport. Keep transportation vehicle clean. Avoid packaging destruction and keep away from impurity.