Nhũ tương VAE là gì và Tại sao Nó Cần thiết trong Công thức Mực in Dựa trên Nước

Định nghĩa và vai trò của nhũ tương VAE trong các hệ thống mực in dựa trên nước

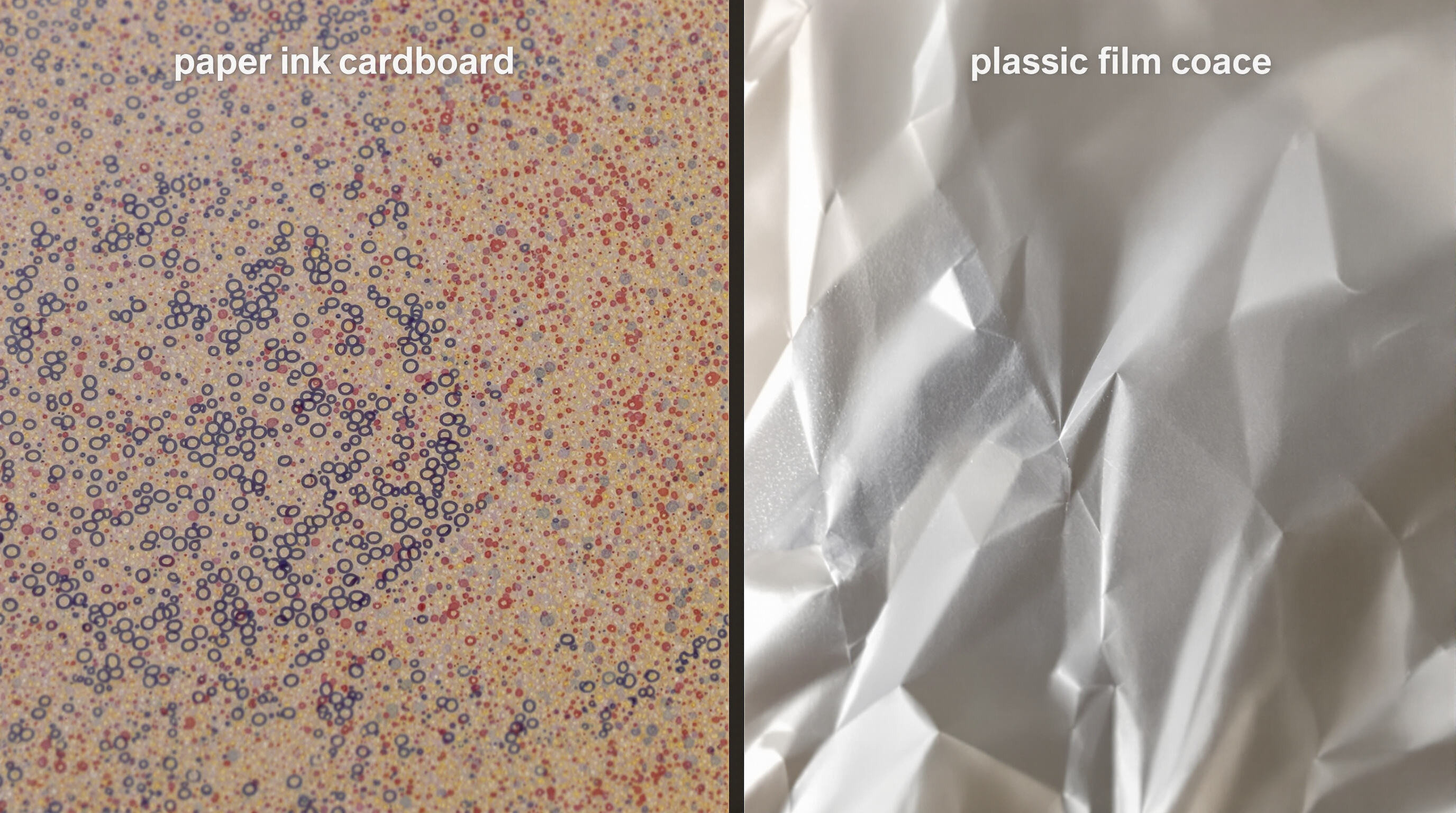

VAE, viết tắt của Vinyl Acetate Ethylene, về cơ bản là một loại polymer gốc nước được tạo thành khi kết hợp vinyl acetate với các monome ethylene thông qua quá trình gọi là đồng trùng hợp. Khi được sử dụng làm chất kết dính chính trong mực in gốc nước, vật liệu này tạo thành các lớp màng rất dẻo dai và bền chắc, bám tốt lên nhiều loại bề mặt như giấy thông thường, thùng carton, các loại vật liệu nhựa khác nhau, thậm chí cả những loại lá kim loại bóng, mà không cần đến các hợp chất hữu cơ dễ bay hơi (VOCs) độc hại thường liên quan đến các phương pháp in truyền thống. Lý do khiến VAE hoạt động hiệu quả là nhờ cấu trúc keo bền vững của nó, giúp phân bố sắc tố đều trong hỗn hợp mực, đảm bảo hiệu suất ổn định ngay cả khi máy in vận hành ở tốc độ tối đa trong quá trình sản xuất.

Thành phần hóa học và độ ổn định trong môi trường nước

Các nhũ tương VAE hoạt động tốt trong môi trường ẩm ướt bởi vì chúng tạo ra sự cân bằng phù hợp giữa vinyl acetate, giúp các vật liệu kết dính tốt hơn, và ethylene, giúp vật liệu không bị cứng quá mức. Hầu hết các hạt đều có kích thước nhỏ hơn 500 nanomet, cho phép các nhũ tương này duy trì sự ổn định khi lưu trữ ở nơi có độ pH dao động từ hơi chua đến trung tính (khoảng 4,5 đến 6,5). Điều này đồng nghĩa với việc nguy cơ vón cục hoặc hư hỏng trong quá trình bảo quản là thấp hơn. Các nhà sản xuất rất ưa chuộng tính ổn định này vì nó giúp kéo dài thời hạn sử dụng lên trên 12 tháng. Trên thực tế, thời gian này dài hơn khoảng 40% so với các chất kết dính acrylic truyền thống, theo nghiên cứu gần đây được công bố trên các tạp chí khoa học về polymer năm ngoái.

So sánh với các chất kết dính thay thế: Acrylic, styrene và nhựa gốc dung môi

Nhựa acrylic có khả năng chống chịu tốt trước tác hại của tia UV, nhưng có một điểm bất lợi là chúng thường cần chất làm dẻo, điều này khiến việc tái chế trở nên khó khăn. Khi nói đến khả năng bám dính trên các bề mặt như màng kim loại, chất kết dính styrene kém hơn khoảng 23% so với hệ thống VAE theo quan sát trong ngành công nghiệp. Các lựa chọn dạng dung môi thải ra lượng VOC cao gấp 5 đến 8 lần so với sản phẩm VAE tương ứng, do đó vi phạm các quy định môi trường nghiêm ngặt như Chỉ thị 2004/42/CE của EU. Với tất cả những yếu tố này, phần lớn các nhà sản xuất mực đang chuyển sang sử dụng nhũ tương VAE. Khoảng hai phần ba số nhà sản xuất đã chuyển đổi sang các nhũ tương này đơn giản vì chúng hoạt động hiệu quả hơn và đáp ứng các tiêu chuẩn bền vững hiện đại mà không tốn kém quá nhiều.

Tăng Cường Khả Năng Bám Dính và Độ Bền Bản In Nhờ Nhũ Tương VAE

Cơ Sở Khoa Học Về Liên Kết Mạnh Với Nền Và Độ Nguyên Vẹn Của Màng

Các nhũ tương VAE tạo ra liên kết cực kỳ mạnh mẽ với các chất nền vì chúng có những chuỗi polymer linh hoạt có thể hình thành các liên kết cộng hóa trị trong khi vẫn giữ được độ bền của màng đủ để liên kết chặt chẽ với nhau. Khi so sánh với các chất kết dính cứng nhắc mà chúng ta thường thấy, copolymer vinyl acetate ethylene hoạt động theo một cách khác. Trong quá trình khô, nó thích nghi và tạo ra các liên kết ngang, dẫn đến sự hình thành các mạng lưới phân tử chặt chẽ không dễ bị bong tróc. Nghiên cứu gần đây từ năm 2024 cũng đã chỉ ra một điều khá ấn tượng. Các thử nghiệm tiết lộ rằng mực in sử dụng VAE có độ bám dính khi bóc (peel strength) tốt hơn khoảng 42% so với các loại mực acrylate thông thường khi được thử nghiệm trên bề mặt kim loại. Khoảng cách về hiệu suất như vậy tạo ra sự khác biệt lớn trong các ứng dụng thực tế nơi độ bền là yếu tố quan trọng nhất.

Hiệu suất trên chất nền xốp (giấy, bìa carton) và chất nền không xốp (nhựa, lá kim loại)

| Loại nền | Độ bám dính (N/m) | Khả năng chống ẩm (%) |

|---|---|---|

| Thấm | 58 ± 3,2 | 89 |

| Không lỗ chân lông | 63 ± 2,8 | 94 |

| Trên các chất nền xốp như bìa carton, tác dụng mao dẫn của VAE cải thiện khả năng thấm sợi, làm tăng độ bền liên kết. Trên vật liệu không thấm nước, sức căng bề mặt thấp của nó (28–32 mN/m) đảm bảo độ ướt và phủ đồng đều. Các bài kiểm tra thực địa cho thấy giảm 30% hiện tượng bong mép trên hộp đựng đồ uống so với mực gốc dung môi, chứng minh độ bền trong điều kiện thực tế được cải thiện. |

Nghiên Cứu Trường Hợp: Cải Thiện Chất Lượng In Và Độ Bền Trong Bao Bì Mềm

Một nhà gia công tại châu Âu báo cáo giảm 57% tình trạng mực in bị bong tróc trên túi đứng sau khi chuyển sang sử dụng mực nhũ tương VAE, được xác nhận qua mô phỏng vận chuyển ISTA 3A. Công thức này có khả năng tải sắc tố cao hơn 18%, ngăn chặn hiện tượng phai màu mà không làm giảm độ dẻo—ngay cả sau 5.000 chu kỳ gập—đáp ứng các yêu cầu của FDA cho bao bì tiếp xúc với thực phẩm.

Khả Năng Chống Mài Mòn, Ẩm Ướt Và Lão Hóa Trong Thời Gian Dài Dưới Điều Kiện Sử Dụng Thực Tế

Các bài kiểm tra lão hóa nhanh (ASTM G154) cho thấy màng VAE giữ được 91% độ bóng ban đầu sau 1.200 giờ tiếp xúc UV, vượt trội hơn 23 điểm phần trăm so với các loại lai styrene-acrylic. Khả năng ổn định thủy phân của chúng ngăn chặn sự thay đổi độ nhớt trong môi trường độ ẩm cao (>85% RH), khiến chúng trở thành lựa chọn lý tưởng cho các hoạt động trong khí hậu nhiệt đới.

Lợi Ích Môi Trường và Tuân Thủ Quy Định của Mực In Dựa Trên VAE

Hàm Lượng Phát Thải VOC Thấp và Phù Hợp với Các Tiêu Chuẩn Môi Trường Toàn Cầu

Các công thức mực dựa trên công nghệ VAE giảm lượng phát thải hợp chất hữu cơ dễ bay hơi khoảng 80% so với các lựa chọn dung môi truyền thống. Điều này giúp chúng tuân thủ các quy định môi trường quan trọng như Đạo luật Không khí Sạch của Cơ quan Bảo vệ Môi trường Hoa Kỳ (EPA) và quy định REACH của EU. Các hệ thống gốc nước thường phát thải dưới 50 gram trên mỗi lít các hóa chất có hại này, mức này thấp hơn nhiều so với giới hạn 250 gram dành cho sản phẩm gốc dung môi. Mức độ phát thải thấp hơn đồng nghĩa với không khí sạch hơn trong các nhà máy và ít rủi ro về sức khỏe hơn cho người lao động phải làm việc lâu dài gần thiết bị in ấn. Nhiều nhà sản xuất đã chuyển sang các lựa chọn thân thiện với môi trường hơn này đơn giản vì họ muốn bảo vệ cả nhân viên lẫn môi trường xung quanh mà không làm giảm chất lượng in ấn.

Giảm lượng phát thải carbon so với các công nghệ mực gốc dung môi

Các nhũ tương VAE tạo ra lượng khí nhà kính ít hơn khoảng 30 đến 40 phần trăm so với những loại nhựa đường truyền thống từ dầu mỏ mà chúng ta đã sử dụng từ lâu. Tại sao ư? Trước hết, quá trình sản xuất chúng đòi hỏi ít năng lượng hơn rất nhiều vì không cần phải sử dụng đến các quy trình xử lý nhiệt độ cao như trước. Ngoài ra, không còn ai phải đốt cháy hàng loạt dung môi độc hại nữa. Và đặc biệt nhất là các nhũ tương này hoạt động rất hiệu quả với những hệ thống sấy tiết kiệm năng lượng hiện đại ngày nay. Một nghiên cứu gần đây của Liên minh Bao bì Bền vững vào năm 2023 cũng cho thấy một điều khá ấn tượng. Khi các công ty chuyển sang sử dụng mực in gốc VAE, chuỗi cung ứng của họ thực tế đã giảm được khoảng 2,1 tấn khí thải carbon mỗi lần sản xuất. Để dễ hình dung, thì con số này tương đương với việc loại bỏ gần nửa nghìn chiếc xe hơi thông thường khỏi đường phố mỗi năm.

Phân tích Vòng đời Sản phẩm: Ưu điểm Bền vững Vượt trội So với Các Hệ thống In Truyền thống

Đánh giá vòng đời đầy đủ xác nhận mực in nhũ tương VAE vượt trội hơn cả các hệ thống gốc dung môi và hệ thống đóng rắn bằng tia cực tím (UV) trên các chỉ số bền vững chính:

| Đường mét | Mực in gốc VAE | Mực gốc dung môi (Solvent-Based Inks) |

|---|---|---|

| Tiêu thụ năng lượng | 18 MJ/kg | 34 MJ/kg |

| Tỷ lệ tái chế | 92% | 68% |

| Tiềm năng độc tính đối với sinh vật thủy sinh | Thấp | Cao |

Ngoài ra, hệ thống VAE hỗ trợ tái chế nước theo chu trình khép kín trong các nhà máy in và đạt mức độ phân hủy sinh học lên đến 98% trong điều kiện ủ công nghiệp.

Tính linh hoạt của nhũ tương VAE trên các kỹ thuật in hiện đại

Tối ưu hóa nhũ tương VAE cho ứng dụng trong in flexographic

Các nhũ tương VAE hoạt động rất tốt cho in flexo vì chúng có thể được điều chỉnh độ nhớt và khô khá nhanh. Khi các nhà pha chế điều chỉnh kích thước hạt polymer trong khoảng từ 0,1 đến 0,5 micron và điều chỉnh hàm lượng chất rắn ở mức khoảng 45 đến 55 phần trăm, điều này giúp cải thiện khả năng truyền mực qua các con lăn anilox mà không làm mất độ rõ nét của hình ảnh. Điều thú vị là việc thực hiện những điều chỉnh như vậy có thể giảm khoảng 40 phần trăm các vấn đề về bọt mực so với các hệ thống acrylic thông thường, theo một số thử nghiệm được thực hiện năm ngoái trên các máy in thực tế.

Thích nghi với Quy trình In Khắc và In Phun Kỹ thuật số

Các nhũ tương VAE về mặt hóa học trung tính, điều này khiến chúng khá đáng tin cậy cho cả ứng dụng in ống đồng và in phun kỹ thuật số. Về mặt in ống đồng cụ thể, các vật liệu này thể hiện hành vi gọi là giả dẻo (pseudoplastic), giúp duy trì độ đồng nhất khi giải phóng mực từ những ô khắc nhỏ thường có độ sâu từ 20 đến 40 micromet. Thị trường in phun mực cũng đã chứng kiến một số phát triển thú vị. Các nhà sản xuất đã bắt đầu điều chỉnh các công thức VAE để chúng hoạt động hiệu quả hơn với hệ thống in phun. Các phiên bản được điều chỉnh này cần có sức căng bề mặt dưới 35 milinewton/mét để tránh gây tắc đầu phun. Và sự điều chỉnh này thực sự cho phép các nhà in đạt được độ phân giải ấn tượng khoảng 1200 dpi trên các loại giấy đặc biệt và các vật liệu không tiêu chuẩn khác mà nhiều khách hàng đang yêu cầu hiện nay.

Tùy chỉnh cho nhiều loại vật liệu nền và nhu cầu hiệu suất công nghiệp

Phân tích thị trường 2024 cho thấy 78% máy in công nghiệp sử dụng mực gốc VAE cho các ứng dụng đa vật liệu nhờ khả năng bám dính linh hoạt của chúng:

| Loại nền | Ưu điểm Hiệu suất VAE |

|---|---|

| Màng Polyolefin | Liên kết hóa học thông qua nhóm ethylene |

| Bề mặt được kim loại hóa | Co ngót thấp trong quá trình đóng rắn |

| Giấy tái chế | Kiểm soát độ thâm nhập (<5 ï¼m độ sâu) |

Nhận định xu hướng: Sự tiếp nhận gia tăng trong lĩnh vực in tốc độ cao và công nghiệp

Xu hướng sản xuất bền vững đã thúc đẩy nhu cầu về nhũ tương VAE trong các dây chuyền đóng gói hoạt động ở tốc độ trên 600 m/phút tăng 62% theo năm. Các nhà phát triển mực hàng đầu chỉ ra rằng VAE có hai lợi thế nổi bật – đáp ứng tiêu chuẩn Zero VOC và hiệu suất cơ học mạnh mẽ – là yếu tố chính thúc đẩy, đặc biệt trong bao bì mềm an toàn thực phẩm nơi các hệ thống đóng rắn bằng tia UV gặp hạn chế.

Công thức pha chế mực nước hiệu suất cao với nhũ tương VAE

Các Thông Số Chính Của Công Thức: Tỷ Lệ Chất Kết Dính, pH, và Các Tác Nhân Đồng Ứng

Để các nhũ tương VAE hoạt động hiệu quả nhất, nồng độ chất kết dính cần được duy trì ở mức khoảng 15 đến 25 phần trăm. Dải nồng độ này giúp tạo ra sự cân bằng tinh tế giữa tính chất bám dính tốt và độ linh hoạt cần thiết. Mức độ pH là một yếu tố quan trọng khác. Việc giữ mức pH trong khoảng từ 8,0 đến 9,0 sẽ ngăn chặn các vấn đề về độ ổn định keo khó chịu phát sinh. Và cũng không thể không nhắc đến các chất kết hợp như Texanol®, thường được thêm vào ở mức từ 2% đến 5%. Những chất này thực sự hỗ trợ quá trình hình thành màng bằng cách cải thiện khả năng kết hợp thực tế của các polymer. Khi các thông số vượt ra ngoài các phạm vi được khuyến nghị này, các vấn đề bắt đầu xuất hiện như vật liệu trở nên quá giòn hoặc mất đi độ bóng đẹp ban đầu. Tuy nhiên, một số thử nghiệm gần đây được thực hiện cụ thể cho các ứng dụng bao bì mềm đã chỉ ra một điều thú vị. Hàm lượng chất kết dính khoảng 18% đã mang lại tỷ lệ bám dính ấn tượng tới 95% khi được phủ lên các bề mặt polyethylene. Hiệu suất như vậy khiến tất cả các thông số này đáng được theo dõi sát sao trong các điều kiện sản xuất thực tế.

Kiểm soát Độ nhớt, Thời gian Khô và Đặc tính Hình thành Màng

Các nhũ tương VAE giúp nhà sản xuất kiểm soát tốt mức độ độ nhớt trong khoảng từ 200 đến 2.000 mPa·s bằng cách điều chỉnh khối lượng phân tử. Điều này giúp mực in chảy đều trong quá trình in flexo đồng thời giảm thiểu sự hình thành sương mù khi vận hành ở tốc độ cao trên các máy in. Một số loại khô nhanh có chứa hỗn hợp chất hoạt động bề mặt đặc biệt, cho phép chúng khô chỉ trong 20 đến 40 giây khi được đun nóng tới khoảng 70 độ C. Thời gian khô nhanh này rất quan trọng để đảm bảo việc căn chỉnh màu sắc chính xác qua nhiều lần in. Các màng VAE được chế tạo đúng cách thực tế có thể đạt độ trong suốt hơn 90 phần trăm, làm cho chúng rõ nét hơn nhiều so với các nhựa acrylic thường chỉ đạt mức độ trong suốt từ 75 đến 80 phần trăm. Sự khác biệt này khá quan trọng trong một số ứng dụng đóng gói nơi độ rõ ràng là yếu tố thiết yếu.

Phân tán Sắc tố Hiệu quả và Tính ổn định Keo trong Hệ thống VAE

Các nhóm carboxylat có trong polymer VAE giúp giữ cho các sắc tố như titanium dioxide và phthalocyanine ổn định thông qua lực tĩnh điện, cho phép đạt được kích thước hạt cực nhỏ khoảng hoặc dưới 5 micron. Chính điều này mang lại độ chi tiết sắc nét cho bản in. Khi nói đến các chất điều chỉnh lưu biến, chúng hoạt động bằng cách duy trì điện thế zeta trong khoảng từ -30 đến -50 milivôn, ngăn chặn hiện tượng kết tụ của các hạt sắc tố. Kết quả là chúng ta có được độ ổn định keo khá tốt. Hầu hết các công thức cho thấy sự thay đổi độ nhớt ít hơn 3% sau nửa năm lưu trữ. So sánh với hệ thống styrene-acrylic, độ nhớt thường thay đổi từ 8 đến 12% trong cùng thời gian đó. Điều này tạo nên sự khác biệt lớn về hiệu suất lâu dài.

Câu hỏi thường gặp

Nhũ tương VAE là gì?

VAE, hay Vinyl Acetate Ethylene, là một loại polymer gốc nước đóng vai trò chất kết dính trong mực in, mang lại tính linh hoạt và độ bám dính mạnh trên nhiều bề mặt khác nhau.

Tại sao nhũ tương VAE được ưu tiên hơn so với các nhựa gốc dung môi?

Nhũ tương VAE được ưa chuộng vì phát thải ít hợp chất hữu cơ bay hơi (VOC), có độ bám dính tốt hơn và phù hợp với các quy định môi trường nghiêm ngặt.

Lợi ích môi trường của mực gốc VAE là gì?

Mực gốc VAE giảm đáng kể lượng phát thải VOC, tiêu thụ năng lượng thấp hơn và có lượng khí thải carbon nhỏ hơn so với mực gốc dung môi truyền thống.

Hiệu suất của VAE thay đổi như thế nào giữa các chất nền xốp và không xốp?

VAE tăng cường độ thâm nhập và độ bền liên kết trên các chất nền xốp, trong khi sức căng bề mặt thấp của nó đảm bảo lớp phủ đồng đều trên các vật liệu không xốp.

Mục Lục

- Tăng Cường Khả Năng Bám Dính và Độ Bền Bản In Nhờ Nhũ Tương VAE

- Cơ Sở Khoa Học Về Liên Kết Mạnh Với Nền Và Độ Nguyên Vẹn Của Màng

- Hiệu suất trên chất nền xốp (giấy, bìa carton) và chất nền không xốp (nhựa, lá kim loại)

- Nghiên Cứu Trường Hợp: Cải Thiện Chất Lượng In Và Độ Bền Trong Bao Bì Mềm

- Khả Năng Chống Mài Mòn, Ẩm Ướt Và Lão Hóa Trong Thời Gian Dài Dưới Điều Kiện Sử Dụng Thực Tế

- Lợi Ích Môi Trường và Tuân Thủ Quy Định của Mực In Dựa Trên VAE

- Tính linh hoạt của nhũ tương VAE trên các kỹ thuật in hiện đại

- Công thức pha chế mực nước hiệu suất cao với nhũ tương VAE