Re-Dispersible Emulsion Powder (RDP)

Description

Overview

Re-dispersible emulsion powder (RDP), polymer emulsion by adding protective colloid and other substances, spray dried, water as a dispersion medium can be re-formed emulsion, polymer powder with redispersibility. It has high flexibility, high weather resistance and high adhesion to various substrates. It is an important additive in dry mortar, which can improve the elasticity, bending strength and bending strength of building materials, reduce shrinkage and effectively prevent cracking.

Product Summary

Index |

WWJF-8010/8020/8023/8040/8044/8050 |

Non-Volatile %≥ |

98.0 |

Bulk Density g/L |

450-600 |

Ash % |

12±2 |

Minimum Film Forming ℃ |

M±2 |

Glass Transition Temperature ℃ |

N±2 |

Average Particle Size |

80-120 |

Fineness %≤ |

2 |

PH Value |

6-8 |

Product Application

Mortar

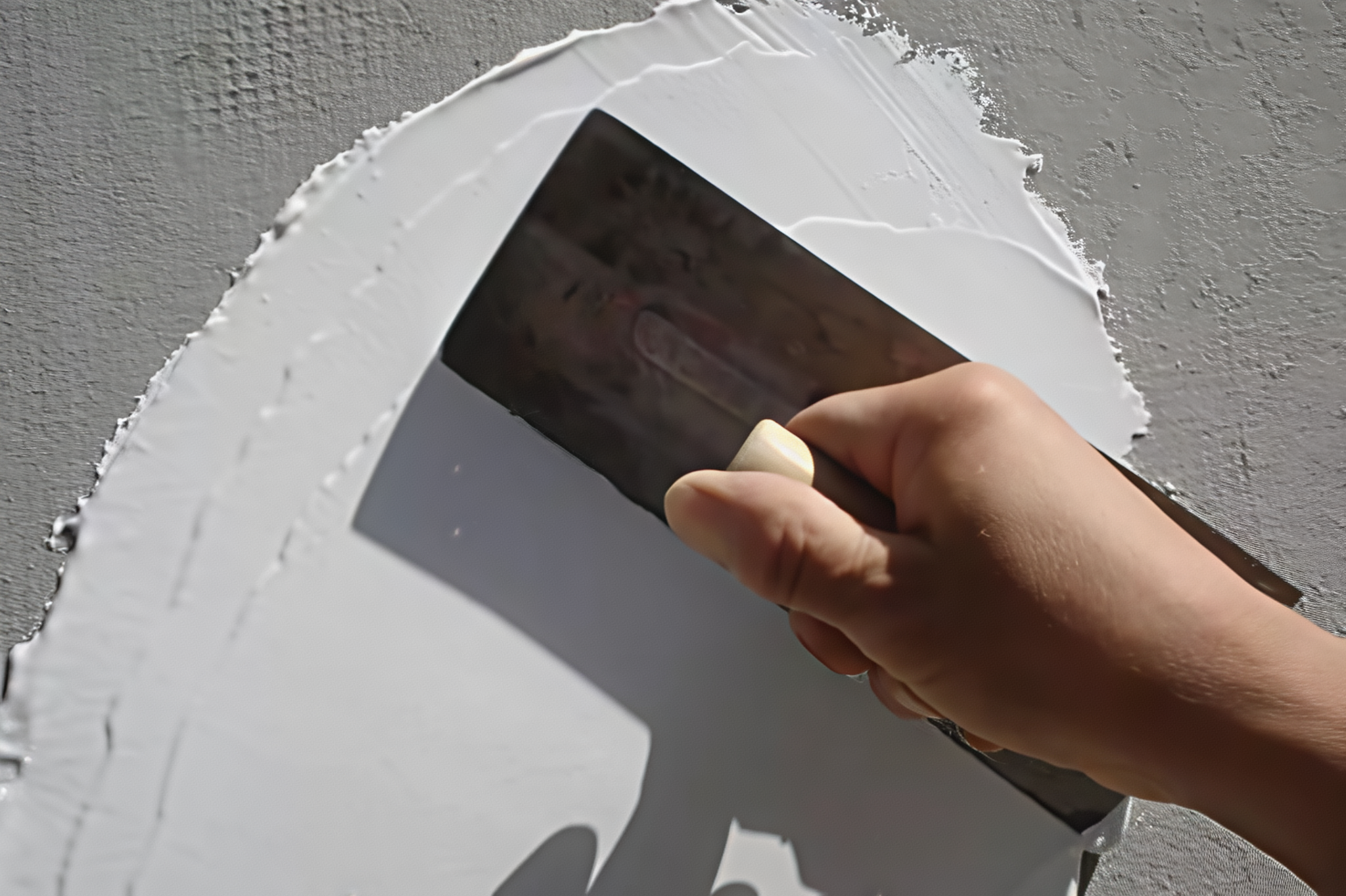

Through polymer film formation and three-dimensional bridging structure, Re-dispersible Emulsion Powder upgrades brittle cement mortar into a flexible composite material. Its core value lies in enhanced bonding (especially for difficult-to-bond substrates), crack resistance and weather resistance (elastic buffering + waterproof and frost resistance) and construction optimization (extended open time + improved fluidity).

Tile Bonding Mortar

Re-dispersible Emulsion Powder forms a composite structure of "rigid skeleton + flexible network" in the mortar, improving the overall performance through the triple mechanisms of film formation and bridging, pore filling and densification, and cohesion enhancement.

Tile Sealant

Through the triple mechanisms of film-forming bridging, pore filling and cohesive reinforcement, re-dispersible emulsion powder upgrades traditional rigid cement-based materials into a modern bonding system that is both rigid and flexible. It has the characteristics of safety, durability, construction friendliness and environmental adaptability.

Interior and Exterior Wall Putty

Re-dispersible Emulsion Powder in putty solves the pain points of traditional cement-based putty such as brittle cracking, powder loss, and water seepage through the triple mechanism of "bonding enhancement-flexible buffering-pore blocking". For exterior wall applications, high addition (1.0%-1.5%) is used to achieve weather resistance protection; for interior wall applications, low-cost trace addition (0.4%-0.6%) is used to improve construction performance and environmental protection.

Package Mark

The packaging of the re-dispersible emulsion powder products shall have obvious and firm marks, including: product name, implementation standard, name and address of the manufacturer, net content, production batch number, certificate of conformity and GB/T191 provisions of "moisture" "sun protection" "prohibited hand hook" and "stacking limit" marks.

Package

20 Kg/bag.

Storage

Re-dispersible emulsion powder stored in a cool, ventilated, dry warehouse, away from kindling, heat. Storage temperature is not greater than 40℃, relative humidity is not greater than 60%.

Transportation

Waterproof, sunproof and fireproof during transportation.

Expiration Date

Under the packaging, transportation and storage conditions meeting the standard requirements, the expiration date of the product is 6 months. If the product exceeds the date, it can continue to be used if it has no agglomeration and meets the standard requirements after inspection.

Safety

Re-dispersible emulsion powder is a powder combustible material. Users should take appropriate safety and health measures. When exposed to high concentrations, they should wear dust masks, antistatic clothing and other labor protection equipment.