VAE Emulsion yog dabtsi thiab qhov tseem ceeb ntawm nws hauv kev tsim cov nta reem tshaj tawm

Ngo leej thiab qhov cim ntawm VAE emulsion hauv cov kev ua nta reem tshaj tawm

VAE, uas yog lus luv luv ntawm Vinyl Acetate Ethylene, yog ib qho polymer uas tsav los ntawm dej uas tau tsim thaum lawv sau vinyl acetate nrog ethylene monomers los ntawm ib qhov kev ua haujlwm uas hu ua copolymerization. Thaum siv nws yog qhov kev ua haujlwm tseemce nrog tshuaj luv dej, cov khoom no tsim cov ntaub ntawv yooj yim thiab zoo uas nyob zoo rau hauv cov ntaub phaj, xov tooj, cov khoom siv hluav taws xob, thiab tias cov khoom siv hluav taws kub, tsis tas yuav tsum tau siv cov VOCs txhaum uas peb feem ntau xav txog thaum peb hais txog cov kev tsim phawb ua ntu kauj ruam. Qhov caij ntawm VAE ua haujlwm zoo heev yog qhia los ntawm nws qhov zoo huv ntawm colloidal uas pab txhawb cov pigment tshwj xeeb rau hauv cov tshuaj luv, ua rau tag nrho cov haujlwm ua haujlwm zoo ib yam xwb thaum cov neeg ua haujlwm tseem ceeb tseem ceeb tseem ceeb.

Cov lus kim thiab qhov zoo huv rau hauv cov dej

VAE emulsions ua haujlwm zoo tshaj plaws nyob rau qhov chaw muaj dej nqaij vim tias lawv muaj kev sib piv txwv yog tias vinyl acetate, uas pab khoom nyob ib leeg zoo dua, thiab ethylene, uas tiv thaiv vajvoob kom tsis txhob yuam kev. Ntau hnub ntim tsawg dua 500 nanometers, uas pab rau cov emulsion nyob zoo thaum ceev nyob rau qhov chaw pH nyob saum npoo ntawm qhov chaw me me lossis sib xws (ntsim 4.5 mus rau 6.5). Nov txhais tau tias muaj meej pem zoo dua los yog tsis tu ncua thaum tseem nyob rau hauv kho. Cov khaub ncaws nyob zoo tias stability vim nws txo ntev dua li 12 hlis. Nyob rau xyoo noj mnem, nws nyob ntev dua li 40% ntau dua li cov acrylic binder feem ntau, raws li kev pab tshawb fwb nyob rau hauv cov ntaub ntawv kho mob polymer xyoo tam sim no.

Sib piv nrog lwm hom binders: Acrylics, styrene, thiab solvent-based resins

Acrylic resins zooj tshwm tau zoo dhau rau UV kauv, tab sis muaj ib qhov yooj yim uas lawv feem ntau xav tau cov plasticizers uas tsis meej ntxiv rau kev roj kom zoo. Txog kev nyiaj ruaj ntseg rau cov ntim siv li metal foil, styrene binders tsis tuaj yeem zoo li VAE systems los ntawm 23% raws li qhov uas kev lag luam pom. Cov khoom siv solvent release tau 5 mus rau 8 zaug ntau dua VOCs kom compared to VAE, uas tsis raug nrog cov luj lawm tshaj plaws li EU Directive 2004/42/CE. Nrog tag nrho cov cuab yeej no nyob hauv pem teb, feem ntau ink producers tau xa mus rau VAE emulsions. Nyob rau sab laug ntawm manufacturers tau xa mus rau cov emulsions no tsuas yog vim tias lawv ua haujlwm zoo dua thiab txhawis tau cov kev tswj ntu mob tshiab tsis tas nqi ntau.

Kev Nyiaj Ruaj Zoo Tshaj Plig Thiab Kev Txaus Siab ntawm Kev Sau Nrog VAE Emulsions

Tus Tsev Ntawv Txog Kev Nyiaj Ruaj Rau Substrate Thiab Kev Nyiaj Ruaj ntawm Film

VAE emulsions tsim qhov hnyav uas ua haujlwm nrog cov ntawv hauv qab vim lawv muaj cov polymer chains uas ua tau cov covalent bonds tab sis feem ntau tsis tawg. Thaum peb sib piv nrog cov binders peb feem ntau pom, cov vinyl acetate ethylene copolymer ua haujlwm ib yam. Ntawm qhov kev lag luam, nws ceev thiab tsim cov kev sib txuas, uas ua rau cov molecular networks uas tsis tawg yooj yim. Qhov kev kho mob dhau los ntawm 2024 kuj tseem pom qhov zoo li cas. Cov neeg ua test tau pom tias cov inks uas tsim los ntawm VAE muaj qhov peel strength zoo li 42% dua cov acrylic options uas feem ntau siv thaum test rau ntawv pov tseg. Qhov zoo li no ua rau qhov zoo hauv kev ua haujlwm nyob rau hauv qhov chaw uas qhov tseem ceeb tshaj plaws yog qhov nyab.

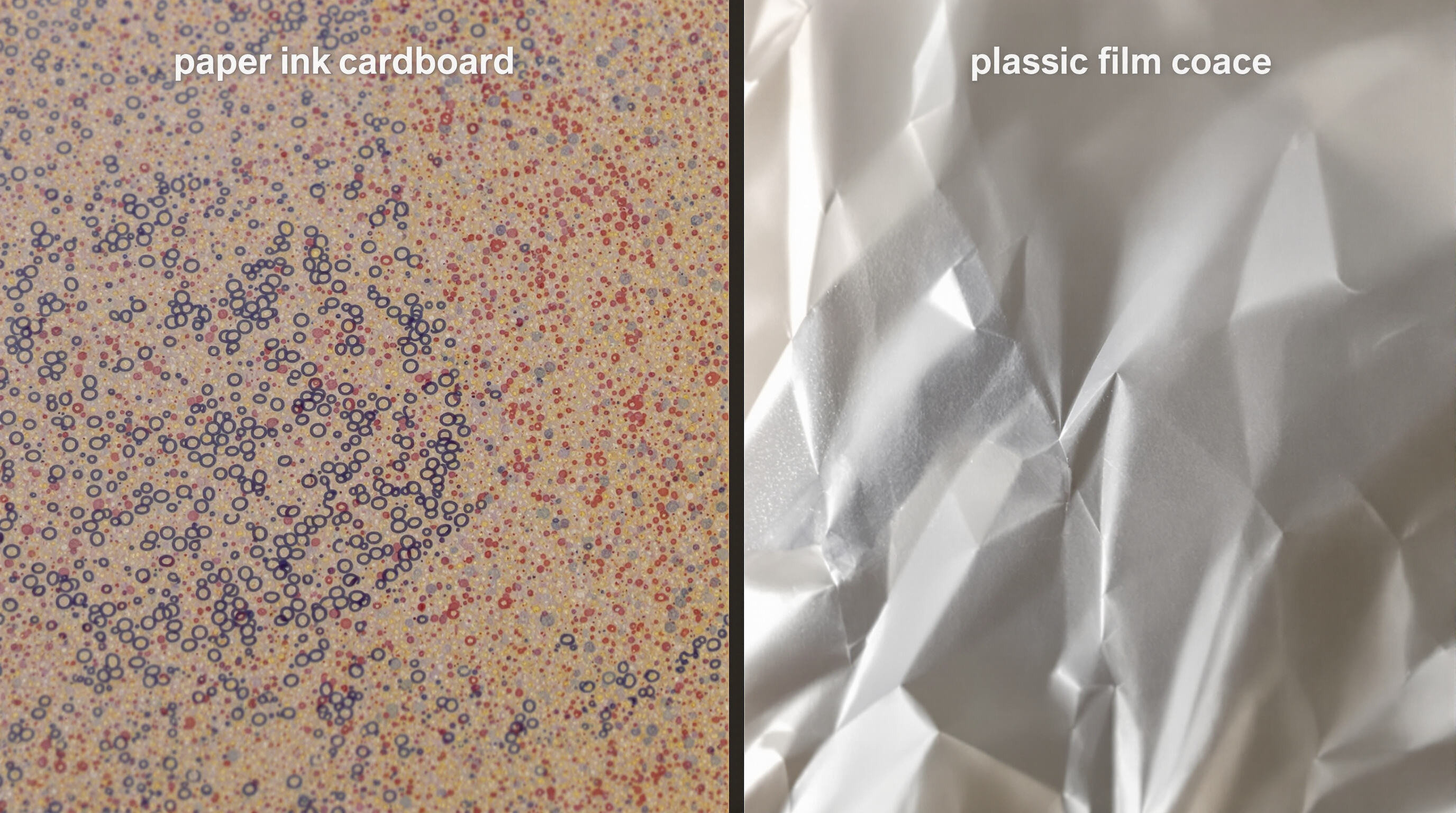

Kev ua haujlwm rau Porous (ntawv, ntawv cardboard) vs. Non-Porous (plastic, foil) substrates

| Hom Ntaub | Adhesion Strength (N/m) | Moisture Resistance (%) |

|---|---|---|

| Porous | 58 ± 3.2 | 89 |

| Non-Porous | 63 ± 2.8 | 94 |

| Rau cov khoom siv hluav taws xob li cardboard, VAE's capillary ua haujlwm pob qab kev kawm ntawm cov ntawv, ua rau kev lag luam siab dua. Rau cov khoom tsis tuaj yeem sib sau, nws qhob chaw qhob (28-32 mN/m) paub tias cov khoom sib npaug thiab cov khoom sib npaug. Cov neeg test test tau pom 30% menos ntawm kev nce sab hauv ntawm cov chaw ua haujlwm ua sijhawm ua haujlwm hla rau cov lus qhia siv tshuab hauv solvent, pom tias lub sijhawm hauv kev nyob ntev siab dua. |

Lub Tsev Cai: Zoo Siab Thiab Nyob Ntev Ntawm Cov Lus Sau Rau Cov Khoom Siv Hluav Taws Xob

Ib tug neeg ua haujlwm hauv Tlhab Ntsiab tau hais tias muaj 57% menos ntawm cov lus qhia rub-off hauv cov pouches ua haujlwm tom qab mus rau VAE emulsion inks, uas tau raug tshawb xyuas hauv ISTA 3A kev sim ua haujlwm. Lub sijhawm muaj 18% siab tagnrho pigment tau tso cai rau tsis txhob sib sau los ntawm kev ua haujlwm zoo dua-ib txwm tom qab 5,000 kev nce qib-ua rau lub FDA cov lus qhia rau cov khoom noj.

Keo Nyob Ntev Rau Kev Sib Txuas, Kev Ntxhov, Thiab Kev Ntxhiab Hauv Kev Nyob Hauv Kev Nyob Hauv Kev Nyob

Cov roj siab hluav taws xob (ASTM G154) pom tias cov VAE films kaw 91% ntawm qhov sawv ntxaws tom qab 1,200 teeb li qhov chaw ua haujlwm rau cov ntaub ntawv ua ntej nrog 23 nplooj ntawv. Lawv cov hluav taws kua sov taws kom tsis txhob hloov pauv ntawm qhov hnyav huv rau cov chaw uas muaj qhov hnyav huv siab (> 85% RH), ua rau lawv yog qhov zoo tagnrho rau cov haujlwm nyob rau qhov chaw ntuj sov.

Kev puas ntsoog thiab Kev Khaws Cai Txog Vajtswm ntawm VAE-Based Inks

Tshaj Tawg VOC Thiab Kev Khoo Tham Rau Lub Koj Hlis Txog Vajtswm

Cov txheej siv VAE technology ua rau VOCs tso tawm siab dua li 80% dhau los ntawm cov nplaum ua ntej. Vim li no, lawv khws nrog cov tswv yam tshwj xeeb xws li cov tswv yam ntawm US EPA thiab EU's REACH. Cov chav siv dej tso tawm VOCs qhov siab tshaj plaws 50g/L, uas yog qhov tsawg dua li 250g/L uas yog qhov siab tshaj plaws rau cov nplaum siv solvents. Qhov tso tawm siab tshaj plaws ua rau lub caij ntuj sov dua hauv cov xov xwm thiab tsawg dua cov nyiam kev nyab xeeb rau cov neeg ua haujlwm uas ua haujlwm ntev hauv qab cov chav tshuaj. Ntau tus neeg tsim khoom lawm hloov mus siv cov khoom ua ntej uas zoo rau ntiaj teb thiab zoo rau cov neeg ua haujlwm thiab tsis txhob ua kom txo qhov zoo ntawm cov khoom tshuaj.

Carbon Footprint Txo Tos Compared to Cov Khoom Siv Solvent-Based Ink

VAE emulsions tsim cov hluav taws xob 30 txog 40% siab dua li cov petroleum-based resins peb tau siv dhau los. Vim li cas? Thaum ua VAE emulsions, lawv tsuas yog xav tau qhov chaw ua haujlwm tsawg dua vim tias tsis muaj kev xav tau rau kev ua haujlwm uas ua rau cov resins rwb thaum ua. Tom qab ntawd, tsis muaj tus twg yuav tsum siv cov solvents ua rau ntub nrov. Thiab tseem zoo dua, cov emulsions no ua haujlwm zoo nrog cov systems siv tshuaj sov kho tshuaj ntawm peb. Ib qho tshawb pom los ntawm cov neeg tshawb nrhiav ntawm Sustainable Packaging Coalition teb chaws 2023 kuj pom ib qho tseem ceeb. Thaum cov chaw ua haujlwm hloov mus siv cov VAE-based inks, cov khw uas muag cov khw ua haujlwm no txo cov hluav taws xob tawm 2.1 metric tons thaum ua haujlwm ib zaug. Txhawm rau ua kom cov lus no qhia tias, nws zoo li peb hloov tawm 500 lub teeb meem uas ua haujlwm los ntawm 100 lub teeb meem ib xyoo.

Kev Tshawb Nrhiav Kev Nyob Txij Li Tam Sim No: Cov Ntse Tseem Ceeb Thiab Zoo Dhau Los ntawm Cov Khw Kev Tshaj Lai

Cov kev txheeb xyuas nyob rau hauv lub neej tag nrho yooj yim tias VAE emulsion inks zoo dua li ob qho kev siv solvent thiab UV-cured systems nyob rau hauv cov metrics sib piv txwv:

| Metric | VAE-Based Inks | Solvent-Based Inks |

|---|---|---|

| Kev Siv Ntau Ntawg | 18 MJ/kg | 34 MJ/kg |

| Txoj kev rov qhia ntau | 92% | 68% |

| Kev phem ntawm ua paug rau dej | Zap | Siab |

Ntsim no, VAE systems pab tso dej rov qab siv nyob rau hauv cov chaw sau npe thiab muaj 98% yooj yim tshav teeb nyob rau hauv qhov chaw composting.

Qhov loj thiab sib txawv ntawm VAE Emulsions nyob rau hauv cov kev sau npe tshiab

Dav mob VAE Emulsions rau kev sau napeej hauv kev sau npe xim tshaj

VAE emulsions ua haujlwm zoo heev rau kev sau npe xim tshaj vim tias lawv tuaj yeem raug tsim los ntawm kev hloov pauv viscosity thiab kuaj cov xim sai. Thaum cov neeg tsim kho kho siv cov duab ntawm polymer particle uas nyob ib puag ncig 0.1 mus 0.5 microns thiab hloov ntau npaum li 45 mus 55% feem, qhov no pab tau rau kev txuas xim zoo dua los ntawm anilox rollers tsis txhob loss image clarity. Qhov yooj yim yog tias kev hloov kho no cuam tshuam rau kev kho tshuab ink misting problem ib puag ncig 40% tshaj li cov acrylic systems tsha saum toj no raws li cov kev sim tau muab tso tseg xyoo no hauv kev sau npe xim.

Kev dav mob rau Gravure thiab Digital Inkjet Printing Processes

VAE emulsions yog qhov tseem ceeb hauv kev ua lej uas ua rau lawv muaj peev xwm zoo rau kev sau ntawv gravure thiab digital inkjet. Gravure printing yog qhov tseem ceeb heev, cov khoom no muaj qhov zoo uas hu ua pseudoplastic uas pab tiv thaiv qhov zoo thaum sau ntawv los ntawm cov lus uas ua rau muaj ntau yam uas ntev li 20 mus rau 40 micrometers. Tus naj npawg inkjet kuj tau pom cov kev pab cuam tseem ceeb. Cov neeg tsim khoom tau hais txog VAE formulas kom zoo dua rau inkjet. Cov khoom zoo dua no yuav tsum muaj kev ncaj ncees hauv qab 35 millinewtons per meter kom tsis txhob tawg cov nozzles. Thiab qhov zoo no pab rau cov neeg sau ntawv pom cov kev zoo li 1200 dpi rau cov duab ntawv tseem ceeb thiab lwm yam uas cov neeg muas khoom xav tau.

Kev tsim raws li qhov xav tau thiab kev zoo li ntau yam thiab kev ua haujlwm ntawm tus kheej

Kev vam rau thej meej hlis 2024 qhia tias 78% ntawm cov ntaub ntawv siv VAE-based inks rau kev siv khoom sib txawv vim li cas nws muaj kev nyiaj ib hnub:

| Hom Ntaub | VAE Txoj Haul Zoo |

|---|---|

| Polyolefin Films | Kev nyiaj kem los ntawm ethylene groups |

| Metalized Surfaces | Kev rov qab tsawg hauv khib |

| Recycled Paper | Kev tswj kom nkag mus (<5 ï¼m depth) |

Trend Insights: Kev Nce Tshaj Hlub Nyob Rau Hauv Qhov Chaw Siv Tshuab Siv Ntau Thiab Siv Ntau

Yav tom ntej feem ntau tshwm sim rau kev tsim kho nyob rau hauv qhov chaw tsim kho, muaj kev nce tshaj 62% xyoo los xyoo tsoom rau VAE emulsions nyob rau hauv qhov chaw pib tsim kho uas tuaj saum 600 m/min. Cov kws tsim ink pom tseeb tias VAE muaj ob qhov txaus siab—Zero VOC compliance thiab kev ua haujlwm zoo—rau qhov tseem ceeb tshaj plaws, tshwj tsis yog rau cov khoom noj yooj yim uas UV-curable systems nyob ze.

Kev Tshuaj xyuas Siv Lub Ntsiab Laij Ua Rau Cov Inks Siv Ntxhuav Nrog VAE Emulsions

Cov Kev Cai Txog Kev Tshuaj Xyuas: Qhov Muaj Zaj, pH, thiab Cov Chaw Coalescing

Yog tias VAE emulsions xav tau kev pab los ua haujlwm zoo tshaj, yuav tsum muaj qhov ntau ntawm cov chaw kuaj xyuas nyob deb li 15 mus rau 25% . Qhov no pab txhim kho qhov kev sib txawv zoo tshaj heev ntawm kev nyob nrog zoo thiab qhov tsim nyog ntawm kev flex. Qhov pH yog ib qhov lom zem tshaj. Yog tias sau nrog qhov pH nyob saum 8.0 mus rau 9.0 ces yuav tiv thaiv kev tsis muaj zog ntawm kev nyob ruaj khov. Thiab tsis txhob nrhiav coalescing agents zoo li Texanol® uas feem ntau tau ntxig nrog qhov ntau ntawm 2% mus rau 5%. Cov khoom no pab ntau nyob rau hauv kev tsim film los pab kev sib tham ntawm cov polymer tau zoo dua. Yog tias muaj dab tsi tsis nyob rau hauv qhov recommended ranges, yuav muaj teeb meem tsha tsha los zoo li khoom loj hlob lossis khiav lub siab hlub. Ib co kev sim tshiab uas tau them nyob rau hauv flexible packaging applications tau pom ib qhov tseem ceeb. Ib qhov binder content ntawm 18% tau muab adhesion rate txog 95% thaum sau nrog polyethylene surfaces. Qhov kev ua haujlwm no pab tau ib qhov tseem ceeb rau kev coj tus kheej nyob rau hauv kev tsim khoom.

Kev Tswj Kev Txias, Sijhawm Kawg, thiab Thaj Chaw Sau Nrog VAE

VAE emulsions pab rau tus khaub ncaws muaj kev tswj siab zoo ntawm kev txias uas tuaj yeem muaj qhov sib txawv ntawm li 200 mus rau 2,000 mPa·s los ntawm kev hloov pauv ntau hli. Qhov no pab tso kom dej nkhw tshuaj nkag tau zoo hauv kev sau nrog tshuaj nkag rau cov ntawv sau nrog tshuaj nkag thaum twg nws tshuaj xyuas nyob rau hauv kev tshuaj nkag ntau. Cov ntxiv tshiab uas tuaj yeem kawg ntev rau li 20 mus rau 40 feeb thaum nws muaj qhov ceev li 70 degrees Celsius. Qhov sijhawm kawg no yog qhov tseem ceeb heev rau kev sau nrog tshuaj nkag ntau uas xav tau kev sau nrog zoo. Cov VAE films uas tsim tau zoo tuaj yeem muaj qhov pom zoo dua li 90% pom, uas tsis zoo li acrylic resins uas feem ntau tsuas muaj qhov pom zoo li 75 mus rau 80%. Qhov sib txawv no yog qhov tseem ceeb rau qhov chaw tshuaj nkag uas xav tau qhov pom zoo.

Kev Sau Ntawv Zoo Thiab Kev Tswj Siab Zoo ntawm VAE Systems

Cov neeg hauv VAE uas pom nyob rau hauv cov chaw tsim kua kim tuaj yeem tiv thaiv cov kua kim zoo li titanium dioxide thiab phthalocyanine los ntawm kev siv lub zog electrostatic, uas pab tau rau cov duab ntau yam me me tshaj 5 microns. Yog li ntawd tus lej uas muaj qhov txuas siab txaus siab. Txog thaum mob thiab kho mob, lawv ua haujlwm los ntawm kev tswj lub zog zeta nyob saum npoo -30 mus rau -50 millivolts, uas tiv thaiv cov duab kua kim kom tsis txav mus ncav. Tus teeb meem uas peb muaj yog ib qho kev tiv thaiv zoo tshaj plaws. Ntau qhov siv tshwj xeej muaj lwm yam tsawg dua 3% hloov pauv nyob rau hauv kev ua haujlwm tom qab nws tau nyob ib xyoo. Sib piv rau cov chaw tsim styrene-acrylic uas kev ua haujlwm feem ntau hloov pauv ntawm 8 mus rau 12% hauv lub sijhawm tseem ceeb no. Muaj qhov sib txawv loj nyob rau hauv kev ua haujlwm xa xaus.

FAQ

Koj pom ntau li VAE emulsion?

VAE, lossis Vinyl Acetate Ethylene, yog ib qho chaw tsim kua kim uas siv nyujav rau hauv cov kua kim, pab rau nws muaj kev ua haujlwm zoo ib txhiab thiab kev tshuaj sib thooj ntau yam rau ntau qhov chaw.

Yuav vim li cas VAE emulsion zoo dua resin uas siv cov khoom siv?

VAE emulsion yog qhov xav tau vim nws tso tsis pub tuaj tag zog (VOCs), muaj kev nyab xeeb dua, thiab sib phim nrog kev cai tswj hwm dej no tsim nyog.

Cov kev txhim kho dej no tsim nyog los ntawm kev siv VAE-based inks yog dab tsi?

VAE-based inks cuam tshuam ntau rau VOC emissions, tsawg dua kev siv hluav taws, thiab muaj carbon footprint leej hnub ntev dua li cov ink tsha yaj tsha tshuab tsha tshuab.

VAE txheej txheem raug txwv ntim rau hauv thiab tsis ntim rau hauv substrates raws li cas?

VAE pab ntxiv kev ncav npab thiab kev nyab xeeb rau substrates ntim hauv, thaum li qhov tension saum npoo tsawg pab rau cov khoom tsis ntim hauv muaj kev ncav npab zoo ib yam.

Daim Ntawv Qhia

- Kev Nyiaj Ruaj Zoo Tshaj Plig Thiab Kev Txaus Siab ntawm Kev Sau Nrog VAE Emulsions

- Tus Tsev Ntawv Txog Kev Nyiaj Ruaj Rau Substrate Thiab Kev Nyiaj Ruaj ntawm Film

- Kev ua haujlwm rau Porous (ntawv, ntawv cardboard) vs. Non-Porous (plastic, foil) substrates

- Lub Tsev Cai: Zoo Siab Thiab Nyob Ntev Ntawm Cov Lus Sau Rau Cov Khoom Siv Hluav Taws Xob

- Keo Nyob Ntev Rau Kev Sib Txuas, Kev Ntxhov, Thiab Kev Ntxhiab Hauv Kev Nyob Hauv Kev Nyob Hauv Kev Nyob

- Kev puas ntsoog thiab Kev Khaws Cai Txog Vajtswm ntawm VAE-Based Inks

-

Qhov loj thiab sib txawv ntawm VAE Emulsions nyob rau hauv cov kev sau npe tshiab

- Dav mob VAE Emulsions rau kev sau napeej hauv kev sau npe xim tshaj

- Kev dav mob rau Gravure thiab Digital Inkjet Printing Processes

- Kev tsim raws li qhov xav tau thiab kev zoo li ntau yam thiab kev ua haujlwm ntawm tus kheej

- Trend Insights: Kev Nce Tshaj Hlub Nyob Rau Hauv Qhov Chaw Siv Tshuab Siv Ntau Thiab Siv Ntau

- Kev Tshuaj xyuas Siv Lub Ntsiab Laij Ua Rau Cov Inks Siv Ntxhuav Nrog VAE Emulsions