Cov lus qhia txog RDP thiab nws txoj hlooj hauv ETICS

Redispersible Polymer Powders (RDP) yog dab tsi?

RDP, loss ntawv sau ua luv luv los yog Redispersible Polymer Powders, tuaj los ntawm kev sib txuas polymer emulsions thiab feem ntau muaj cov khoom zoo li vinyl acetate loss npooj copolymers. Sib pheej nrog dej thiab lawv rov qab los ua rau latex uas tsim nyog rau siv nrog cement-based mortars. Qhov uas tsim RDP zoo heev yog nws tso cai rau nws txhim kho ntau yam sib piv hlo tawm ntawm ETICS systems—cov external thermal insulation composite systems uas tag nrho neeg hais txog tam sim no. Cov khaub ncaws nyiam pom tias kev sib txuas siab dua ntawm cov khoom siv, kev ntxoov ntxooj siab dua hauv cov khoom tiav, thiab kev tshem tshem zoo dua tsha tsha ntau rau kev tawm tsam rau dej. Cov txhim kho no tshwm sim kev txiav txim siab hauv lub chaw tsim kho thaum kev sib raug zoo tsis tu ncua.

Kev Tshwm Sim ntawm Polymer Film hauv Mortar Matrices

Thaum kev huv kho cov mortar, RDP particles tsim ib qho polymer film uas ua haujlwm hauv cov cement matrix los ntawm ib qho kev ua haujlwm ua ob lub sijhawm. Pem hau kauv, cov polymer emulsion sau hauv cov microvoids nyob sab saum toj ntawm cov cement hydrates. Thaum kev huv siab dhau los, cov particles no yuav ua kom muaj kev sib txuas ua ke ua ib qho kev ua haujlwm zoo li ntawd:

- Nyob rau hauv cov inorganic particles ntawm qhov nanoscale

- Kho kom zoo dua li qhov ua haujlwm ntawm kev ua kom hla

- Tsim cov barriers uas ua haujlwm kom tsis txhawb ntxiv rau kev hlawv mus los ntawm qhov chaw muaj dej

Qhov film no ua kom zoo dua li qhov huv kho taws mus rau 40% hn compared ntawm cov mortars uas tsis tau ua kom zoo dua, thaum nws ua kom muaj kev ua haujlwm zoo li ntawm qhov vapor permeability.

Kev ua kom muaj kev sib txuas ntawm RDP hauv Multilayer ETICS Kev tsim

Hauv cov ETICS assemblies, RDP ua kom zoo dua li qhov ua haujlwm hauv cov layers sib txawv:

| Taub | RDP Kev ua haujlwm | Performance Gain |

|---|---|---|

| Bonding Mortar | Txo rau kev sib txuas nrog qhov chaw los ntawm kev sib thooj kem hauv tsev | 30% siab dua nyob rau kev tach tawm |

| Sai sab nraud | Faib tshwm sim rau kub/sijhawm tshwm sim | 50% txo nyob rau kev ruaj ntseg |

| Kev txhim kho cov rooj hlub | Txo rau kev sib txuas ntawm polymer-cement matrix | 25% zoo dua rau kev tiv thaiv |

Qhov chaw tsim kho lej xaiv RDP qib siv rau glass transition temperature (Tg) thiab minimum film-forming temperature (MFT) kom raug rau lub caij uas yuav tsum tau. Lub xaus 2.5-3.5% ntawm RDP feem ntau yog ib qho kev raug zoo ntawm kev ua kom zoo phem thiab kev ruaj khov rau European ETICS kev siv.

Zoo dua rau kev sib txuas thiab kev sib thooj nrog RDP-modified mortars

Yog li cas RDP txhim kho qhov ceev ntawm kev sib poob hauv ETICS

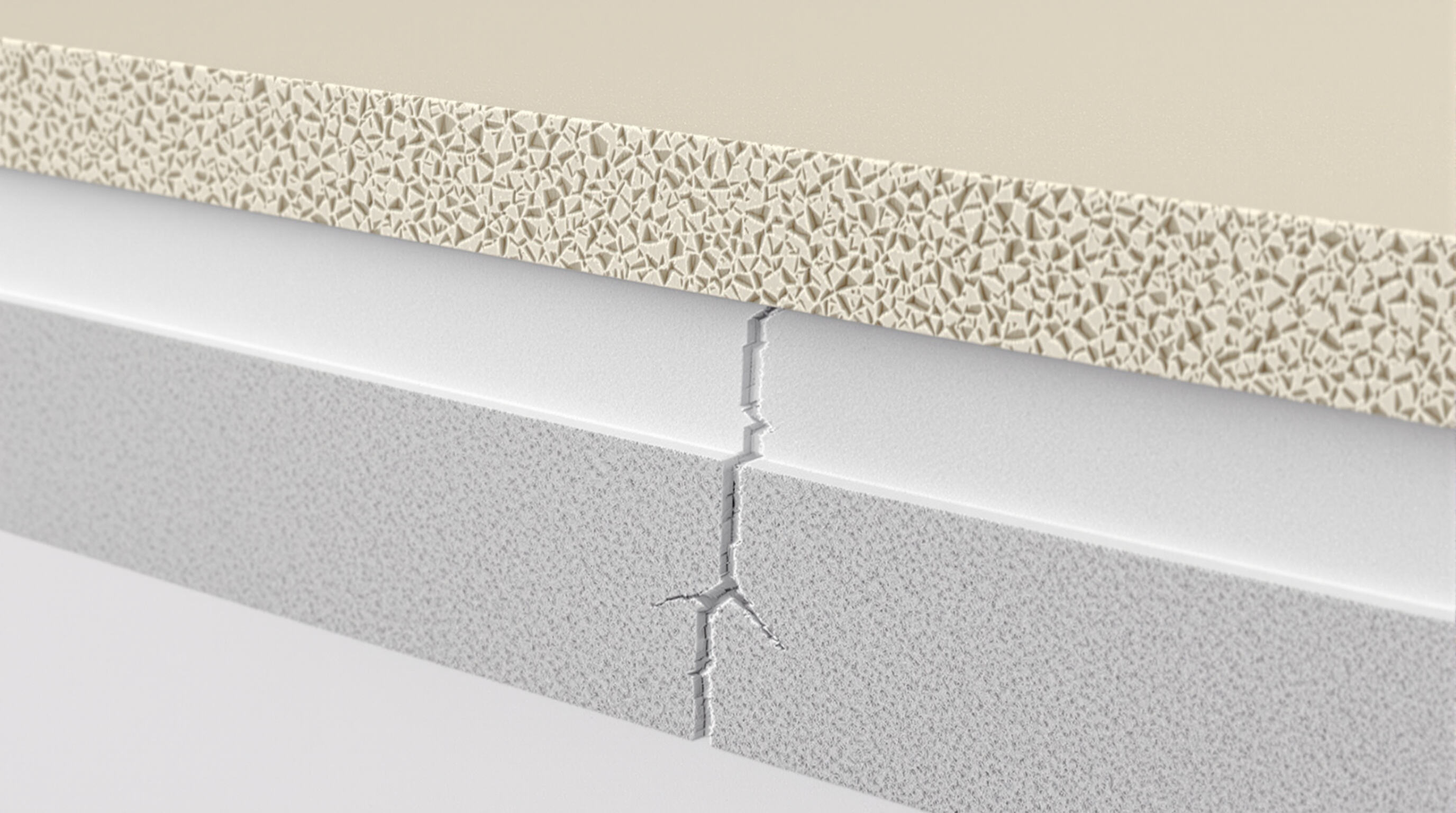

RDPs, loss yog li cas hais tias roj teeb siv tau dua, muab zog ntau rau ETICS los ntawm qhov peb hu ua kev nyiaj ib txwm sib xyuas. thaum xim sab los, cov RDP no tuaj yeem tsim tsoom rau hauv film roj teeb uas tshwm sim nyob saum npoo thiab saum npoo thermal insulation. Qhov tseem ceeb tshaj plaws yog tias kev plooj saum xim sab thiab kev tsim kho roj teeb yuav tshwm sim zog tshaj hauv kev nyiaj ib txwm ntau dua hauv mortar, txawm tias tsis pub tshaj tshuam zog txaus plaib. Thiab qhov no yog tseem ceeb vim tias qhov chaw siv roj teeb tuaj yeem tshwm sim nyob rau hauv qhov chaw sib txawv thiab sib txawv ntawm qhov chaw siv thaum twg muaj zog.

Kev sib poob nyob saum npoo ntawm cov khoom siv tshuab thiab cov ntaub ntawv nruj

Cov mortar uas muaj RDP tau muab kev sib poob zoo tshaj rau hauv cov khoom siv ETICS tshaiv:

| Hom Ntaub | Txhim kho kev sib poob | Hom kev pab tseem ceeb |

|---|---|---|

| Expanded Polystyrene | 30-150% | Tiv thaiv kev tshem tawm thaum muaj zog ntawm dej tso |

| Daim ntawv kho | 70-200% | Txuag nyob rau hauv qhov kub txias |

| Tog nkhaus u tuag | 100-300% | Qhov yas yas rau sab nraud ntawm tsev |

Qhov kev sib cuag no los ntawm RDP tau mus rau hauv cov rooj tsim thiab tshuav nrog cov duab uas tsis txhob tso tseg nyob rau sab nraum ntawm cov khoom.

Kev lag luam RDP rau cov tog nkhaus siv tshuab zoo

Cov neeg lej RDP feem ntau yog 2-5% nyob rau hauv cov tog nkhaus tog. Qhov tsawg (<2%) tsis muaj zog, tab sis qhov ntau (>5%) tuaj yeem faib kom txias. Cov ntaub ntawv los ntawm qhov chaw nyiag siab dua qhia tias 3% RDP muaj:

- 28 hnub tensile adhesion ≥ 0.5 MPa (EN 13499 standard)

- Kev tshuab nyob tom qhov tsis muaj dej tuaj ntau dua li 85%

- Sijhawm siv ntau tshaj 15-25 feeb rau kev hloov kho rau qhov chaw nyob

Cov ntxig uas tsim nyug los ntawm kev sau ua ke RDP nrog cov khoom siv khaws tiv thaiv dej, txhim kho kev siv zoo nyob rau qhov chaw muaj dej ntau thiab tsis txhob kho sijhawm siv.

Kev yooj yim, kev tiv thaiv kab ntsug, thiab kev daws teeb meem nyob rau hauv tsev lag luam

RDPs txhawb kev yooj yim thiab tiv thaiv kab ntsug

Thaum muab ntxiv rau hauv roj teev tsev, cov duab ntawm cov chaw tsim kho nyiaj uas tuaj yeem rov siv tau thaum siv hneev nyob hauv qhov chaw siv cement thiab tsim ib qhov film pib uas txawj txheej. Qhov film no tuaj yeem pib kev ua siab ntau dua li 65% hn compared to regular mortars without these additives. Qhov uas pom tseeb yog tias cov duab polymer no nyob ze rau qhov chaw uas muaj qhov khoob me me uas tsim tshiab los ntawm yam khoom zoo li kub lossis thaum chaw nyob sab nraud hloov. Los ntawm qhov no, nws tso cai rau qhov khoob tsis txawj ntxiv vim qhov kev puas tsuaj raug sib tshuam rau hauv qhov mortar layer thiaj li tsis tsum ruav rau ib chaw. Sau lub mortar uas muaj feem ntau li 3% RDP. Cov khoom no tuaj yeem tiv thaiv kev hloov pauv dua li 0.5 mm per meter ua ntej los ntawm kev phom sij, uas yog qhov tseem ceeb heev rau qhov chaw uas kub hloov pauv ntau, txawm tias tuaj yeem hloov dua li 40 degrees Celsius thaum cov xyoob hloov.

Qhov kev tiv thaiv kev puas tsuaj rau hauv Basecoat Mortars

Lub roj noj muag siv RDP technology tsis zoo li lub roj noj muag tsha tshaj tshiab thaum txheej txheem nrog kev puas tsuaj. Txij li ntawm kev phom los ntawm kev nyha nyuaj li lub roj noj muag tsha tshaj, cov roj noj muag no tuaj yeem khiav thiab nqaj, ntaus siab kev puas tsuaj ua vor rau thaum twg nws tuaj yeem puas tsuaj. Cov kev sim tau qhia tias thaum muaj dej tog tog lossis dej chaw, lub network polymer hauv no tuaj yeem khiav ntau dua li 50% ntxiv rau ib yam khoom tsha tshaj, uas txhais tau tias khoom no txhaws nrog kev puas tsuaj thim tsis phom tas mus. Qhov uas tsim nyog rau qhov no yog nws kev ua haujlwm zoo hauv kev siv roj noj muag thawj zaug. Nyob rau qhov chaw nyuaj uas board insulation raug ib leeg, kev puas tsuaj feem ntau tuaj yeem cuam tshuam thiab tsim teeb meem thaum siab. Tab sis vim qhov kev tsis zoo heev ntawm RDP, cov chaw puas tsuaj no raug xa tso pov nteev hauv saib, kom tswb tsis tuaj yeem tsim nyog rau qhov chaw tseem ceeb no.

Sib cuam tshwm sim ntawm Elasticity thiab Rigidity hauv Render Layers

RDP dosage zoo tshaj plaws (2-4% los ntawm pheej weight) tsim ib qhov kev sib txig txig:

- Hlub ntsiab elastic : Qhov chaw muaj polymer absorb tau 90% ntawm kev puas tsuaj cyclical

- Hlub ntsiab rigid : Lub matrix cementitious tshem tawm zog txwv kom zoo (>15 MPa)

Qhov ntau tshaj plaws RDP (>5%) tuaj yeem cuam tshuam rau plasticity, los phom sij kev tiv thaiv tso rau hail lossis kev rub

Txhim kho qhov ntau ntawm RDP rau dynamic loading thiab kev sib dhos nrog dej num

Ntaub ntawv los ntawm cov haujlwm ETICS nyob Europe sau tias:

| Dej num Zone | RDP % zoo tshaj | Cov kab ntsug ncav (%) |

|---|---|---|

| Mediterranean | 3.2% | 72% |

| Chaw tsov dav hlau | 4.0% | 65% |

| Maritime | 2.8% | 68% |

Rau qhov chaw uas muaj dej nyuaj siab, kev sau ua ke ntawm 3.5% RDP nrog cov sib puag los yog cov duab twg polypropylene tau txais dua li 25 xyli ntawm kev nyab xeeb nyob rau hauv av 150 mph.

Kev Tiv Thaiv Ntawm Hlau, Kev Nyob Dav, thiab Kev Nyob Zoo Ntev ntawm RDP-Enhanced ETICS

Kev Thoov Hlau Thoov Thaiv thiab Kev Nyob Zoo Nrog Ntawm Kev Tsim Hlau

RDP ua haujlwm los txo kev dub hlau ntawm ETICS mortars vim nws tsim cov npliag hlau uas ua haujlwm los khawb cov npeev hlau leeg uas tsawg heev. Cov kev ceeb toom qhia tias cov npliag hlau no tuaj yeem txo kev hlau hauv cov khoom siv los ntawm txog li 60% thaum peb pom cov khoom siv polymer modified renders nyob rau hauv kev sib cuag zoo li nyob rau hauv kev nyob zoo. Cov RDP version acrylic ua haujlwm zoo heev rau qhov chaw uas muaj dej ntau. Lub qhov zoo ntawm kev nyob zoo los ntawm cov npeev hlau thiab cov ntaub ntawv qhia tias cov neeg ua haujlwm nyob rau hauv cov chaw nthuav plawg thiab cov chaw ua si qhia tias lawv muaj kev txo ntawm 72% rau kev kho cov hlau thiab cov npeev hlau uas ua rau cov hlau hlau thiab cov hlau hlau hlau uas ua rau cov hlau hlau hlau.

Kev Nyob Dav Thiab Zoo Los ntawm Kev Sib Cuag Ntev thiab Cov Ntaub Ntawv Nyob Ze

ETICS muaj 3-5% RDP tshuav 95% zog ntawm kev nyiaj sib ntxiv tom qhov chaw npau tsheb 150 xyuas (Fraunhofer IBP, 2023). Nyob rau hauv qhov chaw dej nkhaus, cov rooj pov txoos saum toj muaj RDP uas raug sib thaus los ntawm dej mu salt 5,000 teev tau pom tias muaj qhov ntxiag siab 40% tsawg dua li cov tsis muaj kev pab. Cov ntaub ntawv txog kev ua haujlwm nyob Northern Europe yoojyim tias cov chaw muaj RDP tuaj yeem tshuav qhov ntxiag tsis surpass 0.3 mm tom qab 12 xyli-ua tseem ceeb rau kev tswj kom tsis txhob muaj kev phom sij rau insulation.

Kev Tshawb Nrhiav Tus Xyoo Ua Haujlwm thiab Kev Ua Haujlwm Nyob Rau Hauv Qhov Chaw Txwv Ntawm Europe

Txhia li cov ntaub ntawv txog dej thiab ntuj, cov ntoo uas muaj RDP kho tawm ETICS yuav tsum nyob dav dav hauv 35 xyoo rau qhov chaw xws li Teblias uas tsis muaj dej ntuj loj heev. Nyob rau hauv qhov chaw Mediterranean, cov ntaub ntawv RDP uas muaj UV zoo li ntawd txo cov ntaub ntawv hlob tawm hauv 22% thaum sib piv rau cov ntaub ntawv saum npoo. Nyob rau hauv Scandinavia, cov ntaub ntawv no tseem muaj kev zoo li ib yam. Cov kev kho tawm elastic nyob hauv 15 txog 18%, uas pab cov ntaub ntawv tiv thaiv dej ntuj loj heev uas peb pom hauv qhov chaw ntawd los ntawm minus 30 degrees Celsius rau hauv hav thiab txog 25 degrees rau hauv xyoo ntoo. Tseem ceeb tshaj, qhov ua haujlwm no txiav txim siab nrog cov kev cai ua tiav uas tso tawm hauv EN 13950 nrog 98% kev ua tiav.

Kev nyab xeeb, Siv Hluav taws Kev Nyab Xeeb, thiab Cov Nqis Zoo ntawm RDP rau hauv ETICS

Cov Nqis Zoo ntawm Kev Nyab Xeeb Hluav Taws rau hauv Cov Ntaub Ntawv RDP-Kho Tawm

RDP-thaum muaj zog tshuab kho rau qhov muaj nyuj yaj hauv ETICS los ntawm kev txav qhov chaw sib txig ntawm qhov muaj nyuj yaj. Cov ntaub ntawv polymer-modified tau txais cov nyuj yaj zoo dua 15% zoo dua com pared to conventional renders, translating to measurable energy savings over a structure’s lifecycle.

Kev Puav Txheej Txheem thiab Kev Tsws Nrog rau Kev Rwm Siab Muaj Caij Nyoog

Kev daws teeb meem txheem pom tseeb tias cov kev lag luam RDP-modified ETICS systems ua rau roj carbon hlawv tsawg dua 18-22%pared to traditional cement-heavy compositions. These systems contribute to 6-8 LEED points hauv qhov muaj nyuj yaj thiab cov khoom siv, pab tswv yim rau kev tswj caij nyoog EU taxonomy criteria rau kev kho tshuab nyiam xeeb

Kev Siv Tau Zoo, Open Time, thiab Qhov Kev Nyob Xyoo nrog RDP Mortars

RDP txhawb kev ua haujlwm ntawm cov mortar rheology, nce ntau sai rau 30-50 feeb 30-50 minutes - tseem ceeb rau cov projek ETICS loj. Cov neeg ua tshuab sau tias muaj 40% tsawg dua cov lus teb haujlwm thaum siv cov RDP, tshwj xeeb rau cov kev ua haujlwm uas muaj kev nyuaj xws li cov pob ntawd. Qhov kev cuab yeej no txhawb kev ua haujlwm zoo thiab nce ntau sai thiab ua rau qhov chaw tsis muaj kab ntsaws nyob rau hauv kev nce sai ntawm nruab (≥25 m/s).

FAQ

Kuv yuav tsum paub txog cov zoo li cas thiab los ntawm kev siv RDP hauv ETICS?

RDP txhawb kev nyob hauv qab, kev ua haujlwm zoo, kev tiv thaiv dej, thiab kev tsim khoom zoo rau cov khoom siv hauv ETICS systems, ua rau zoo dua nyob rau hauv qhov chaw uas muaj kev hloov pauv.

RDP yuav ua li cas txhawb kev nyob hauv qab ntawm kev nqum?

Cov RDP particles ua cov polymer films uas tuaj yeem ua haujlwm zoo, uas txhawb kev nyob hauv qab ntawm kev nqum los ntawm kev sau rau qhov chaw nyob sab saum thiab sab hauv ntawm cov khoom siv thiab cov khoom insulations.

Koj yuav tsum siv RDP ntau npaum li cas rau cov kev siv hauv ETICS?

Cov RDP yuav tsum siv ntau npaum li 2-5% ntawm qhov hnyav, xws li qhov kev ua haujlwm zoo thiab qhov chaw uas nyob.

Puas yog ETICS uas tau hloov los ntawm RDP tu siab dhau qhov cua txias nyuaj?

Yog, qhov tshwj xeeb ntawm RDP pab them rau ETICS kom tu siab dhau qhov cua txias nyuaj, suav nrog qhov kub txias txiav txim, zog ntawm dej noo, thiab dej hluv.

RDP pab tso rau kev tsim khoom nyob qhov twg?

Qhov chaw tsim khoom ETICS uas tau hloov los ntawm RDP reduce embodied carbon thiab pab txheej siv ntau zog dua, pab rau kev tswj hwm kho tsev xeev thiab kev ua lag luam nyob

Daim Ntawv Qhia

- Cov lus qhia txog RDP thiab nws txoj hlooj hauv ETICS

- Zoo dua rau kev sib txuas thiab kev sib thooj nrog RDP-modified mortars

- Kev yooj yim, kev tiv thaiv kab ntsug, thiab kev daws teeb meem nyob rau hauv tsev lag luam

- Kev Tiv Thaiv Ntawm Hlau, Kev Nyob Dav, thiab Kev Nyob Zoo Ntev ntawm RDP-Enhanced ETICS

- Kev nyab xeeb, Siv Hluav taws Kev Nyab Xeeb, thiab Cov Nqis Zoo ntawm RDP rau hauv ETICS

-

FAQ

- Kuv yuav tsum paub txog cov zoo li cas thiab los ntawm kev siv RDP hauv ETICS?

- RDP yuav ua li cas txhawb kev nyob hauv qab ntawm kev nqum?

- Koj yuav tsum siv RDP ntau npaum li cas rau cov kev siv hauv ETICS?

- Puas yog ETICS uas tau hloov los ntawm RDP tu siab dhau qhov cua txias nyuaj?

- RDP pab tso rau kev tsim khoom nyob qhov twg?