RDP yog dab tsi thiab nws ua haujlwm li cas hauv dej nkhis tshuab?

Nyeem qhia thiab sau npe ntawm cov duv pov duab (RDP)

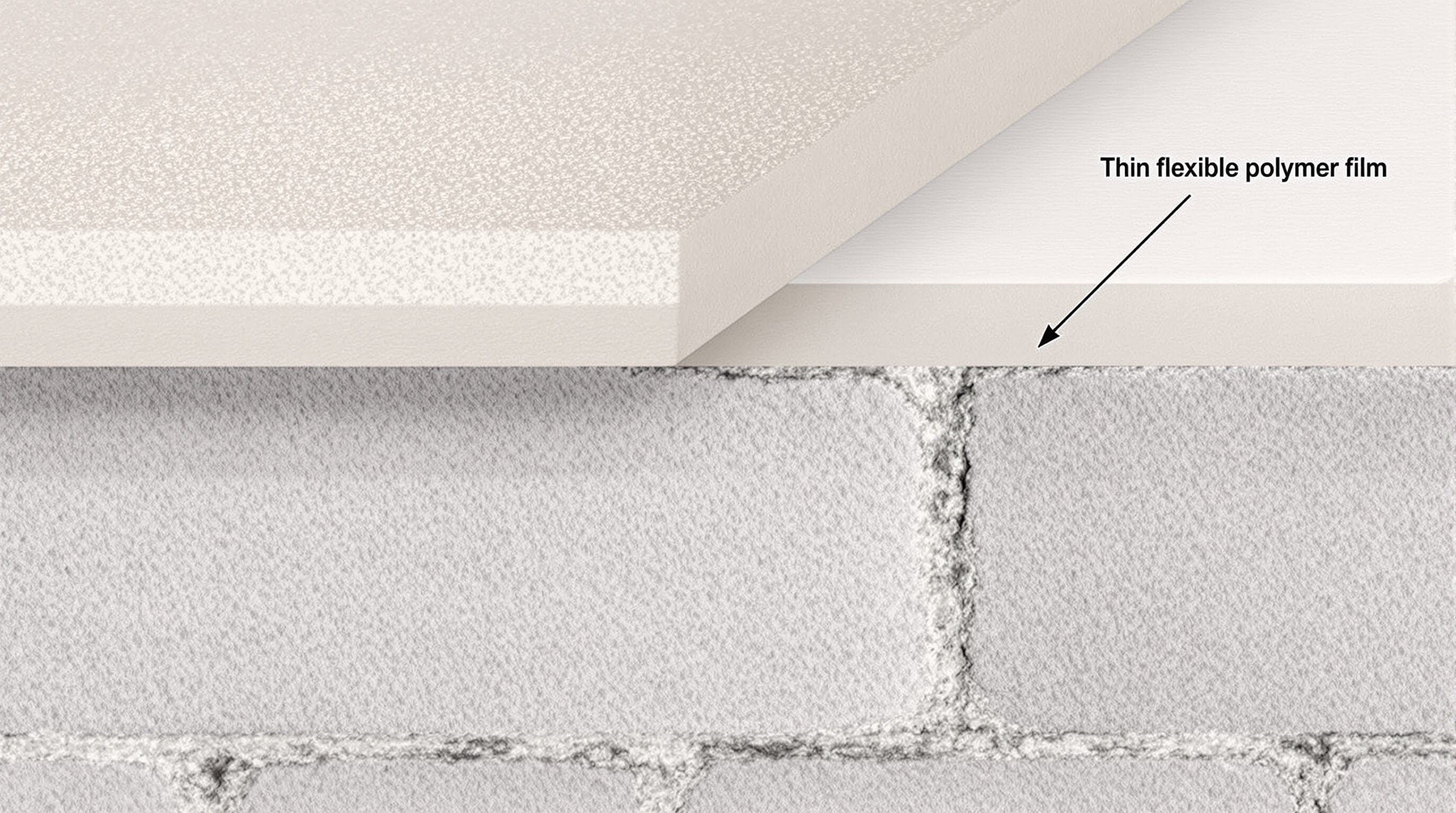

Daim ntaub polymer uas tuaj yeem rov siv dua, uas feem ntau hu ua RDP, muaj cov chaw kuaj xyuas polymer nrog rau cov chaw tsham kuv thiab cov khoom pab tso tsis pub kom phom. thaum nyob hauv qhov chaw kuaj, qhov khoom no yuav xwm txawj li lwm yam ntaub meej uas tuaj yeem sau ua ib txoj haujlwm lossis xa tau ntau yam. tab sis yuav muaj kev hlo li cas thaum muaj dej ploij. Sib puag rau RDP nrog dej yuav cuam tshuam nwsกลับมาเป็นน้ำยางเสถียร. qhov kev txwv no pab rau daim ntaub kom sib thooj nrog rau cov khoom siv cement hauv kev tsim kho. qhov uas pab RDP zoo tshaj plaws yog nws pab txhim kho ntau yam kev txwv. nws pab ntxiv kev ua si nrog, thiab pab ntxiv kev sib xyaw nrog rau qhov chaw. nyob ib txwv ntawd, nws pab tso ntau tiam siab tias tsis txhob muaj dej ploj. nyob ib txwv ntawd, nws pab tso ntau tiam siab tias tsis txhob muaj dej ploj. yam uas zoo tshaj plaws yog tias tag nrho cov kev pab no tuaj nrog tsis ua rau qhov sib thooj nyuaj rau siv hauv cheeb kam.

Kev cai ntawm kev rov siv thiab kev tsim cov ntim polymer hauv mortar

Thaum siv nrog dej, RDP cov duab ntxos rov qhib los ua lub thawj qhov chaw sib txuas thiab sib xyaw ntau yam li tshwj xeeb hauv mortar mix. Thaum kev sib sau ua leej li cas thiab dej rov qab los ntawm kev kuaj, cov duab polymer no rov muaj ib qho film uas muaj peev xwm zoo dua thiab sib tshooj rau hauv cov cement hydrates. Qhov tshwm sim yog ib qho kev sib txig sib toog uas pab txheej tau cov qhov raj nyob hauv khoom siv thaum kuj pab nws zoo dua hauv kev tiv thaiv kev puav tswj. Ib co kev suav sau tseg tias qhov no tuaj yeem cuam tshwm ib feem tshiab dua li mortar tsis muaj kev hloov pauv, uas txhais tau tias nws zoo dua txaus plua pluag thaum muaj kev puav tswj thiab kev sib thlub hauv kev siv nyob ze tagnrho.

RDP nyob hauv kev siv siv tshuaj nyob hauv kev tsim kho

RDP-modified mortars muaj peev xwm txaus siab tshiab txaus siab:

- Zoo dua hauv kev sib txig sib toog : Lub polymer film sib xyaw ntau yam li tshwj xeeb hauv kev puav tswj, kom cov raj tsis loj dua

- Zoo dua hauv kev sib txig rau substrate : Lub ntau yas ntawm latex rov qab mus rau hauv cov raj, tsim kho kom nyeej tshaj

- Kev tso siab rau dej num : Qhov chaw sib txig uas muaj polymer-cement txhim kho tso siab rau kev cuam tshuam los ntawm kub txog 50°C thaum twg tseem muaj kev nyeej

Qhov chaw sib txig organic-inorganic no muab kev pab hauv kev siv ntau yam xwm yeem zoo li exterior insulation and finish systems (EIFS), qhov uas yuav tsum muaj kev nyeej thiab kev ua tau ntau lawm

Txhawb kev nyeej: RDP ua li cas txhim kho kev nyeej ntawm mortar thiab substrate

RDP muaj feem nyob rau saib xyuas kev nyeej ntawm rendering systems

RDP fe tsis nyooj li ib tug kheej tshwj xwm ntawm mortar thiab ltxiag, xws li concrete lossis brickwork. Thaum nws dhau los, cov khoom no tau ncav rau hauv qhov chaw me me uas peb tsis pom thiab tsim kho kev sib txig nyob rau hauv saub hlis. Cov kev suav zais tau qhia tias no pab tiv thaiv cov khoom nyob ib leeg zoo li 40% dua li cov ntaub ntawv tsim kho tsha yam ntxiv raws li kev suav zais los ntawm Ponemon nyob rau 2023. Qhov tseem ceeb yog RDP muaj cov cuab yeej sib txawv uas pab rau dej txuas mus rau hauv qhov chaw loj. Qhov no muaj tseeb tshaj plaws thaum ua haujlwm rau hauv cov haujlwm uas muaj kev puas tsuaj, xav txog insulation rau cov tsev nyob sab nraum. Qhov kev sib txig ntau dua ntawm cov kab tuaj yeem sau nrog cement tsis tuaj yeem ua tau li cas lawm, tshpecially thaum nrhiav khoom rau sab saud vim nws yuav tsis txwv nqes ntau. Cov neeg ua haujlwm tau pom qhov sib txawv no nyob rau hauv kev tsim kho sab khaug.

Kev Tsim Kho Polymer Film Thiab Nws Txheej Xwm Rau Bond Strength

Thiab chaw ua mortar npog, RDP tsim ib qhov sib txuas ncaj ncees uas nyob nrog cement hydration khoom. cov neeg tau txais ib qho kev tsim nyob ob qhov uas tso tawm zog ntawm 28%, tab sis tsis txhob muaj zog siab heev rau kev tiv thaiv kev sib thooj sib thaub los ntawm kev hlo li cas raws li kev xam zoo tshaj tsaus los ntawm JCT xyoo no. kev test nyob hauv kev nyab suab pom tias cov mortar sau ua no tuaj yeem nyob nrog cov ntoo npog ntxos nrog zog npog dua 1.5 MPa, uas yog qhov tseem ceeb rau cov ETICS facades nyob rau qhov chaw muaj dej phem. tom qab ntawv, qhov kev sib txuas no tsis yog tsuas yog zoo rau zog xwb. nws tuaj yeem rov qab thiab nqes nrog cov ntaub ntawv leej twg leej kuj tuaj yeem rov qab, kom txo kev npog dua li ib feem pua cuaj dua li cov systems tsis muaj kev pab ntau li.

Kev Tshawb Fwm Nyob Zeem Tsheej: Daim Ntawv Sau Siv Rau Lub Ntim Hlis

Kev saib xyuas 42 tog chaws ntev nyob rau sab nraud ntawm qhov pob ze hauv xyoo 2024 tau tso caij tau txais lwm yam kev pom zoo txog kev ua haujlwm ntawm mortar. Mortar muaj 3% RDP tau kawm ib leeg li 98% ntawm qhov siab thaiv tom qab sib zog dhau ib xyoo, thaum uas cov siv siv tshwj xeej tsuas yog muaj ib leeg li 72%. Ib qho kev pib tseem ceeb tshaj plaws yog tias cov ntaub ntawv no tau nyob dhau 150 zaug ntawm khib nyiab los ntawm -20 degrees Celsius mus rau +60 degrees Celsius tsis muaj dab tsi phom sij. Qhov no hais tau tias RDP zoo li cas rau kev tsim cov rooj av tsha tshaj tawm uas nyob ntev thiab zoo dua.

Txhim kho kev tiv thaiv kab ntsug thiab qhov siab thaiv tom qab sib zog nrog RDP

Cov teeb meem ntawm kab ntsug nyob rau hauv cov mortar tsim tsha tshaj tawm

Cov roj tog nkhaus tshuab cement nyob rau hauv qhov kev tsim los yog qhov khaum, 40–60% yuav ploj siab tom qhov chaw rau hauv ib xyoo pib los ntawm qhov txias thiab qhov ceev. Qhov tsawg tshaj plaws ntawm qhov ntau (1–2 MPa) thiab qhov tsawg tshaj plaws ntawm qhov hla (0.01–0.03%) ua rau cov roj tog no yooj yim ploj siab thaum lub sijhawm siv, vim tias qhov tsho lossis dab tsi feem ntau yuav tshwm sim qhov ceev hauv plua pluas uas loj dua qhov tshuab tuaj yeem thlaj tau.

Yuav li cas RDP pab ntxiv qhov zoo hauv kev hla thiab qhov hla

RDP muab ib qhov chaw polymer sib txuas rau hauv peb qhov tebchaws uas pab ntxiv qhov hla los ntawm 400–700%. Thaum muaj dej, nws tsim ib qhov film uas txuas ntxiv cov khoom uas tsim los ntawm cement, pab kom muaj qhov hla txog 5% tsis ploj siab. Cov kev ua lej tseem ceeb yog:

- Kev txuas hauv qab zib : Cov duab ntawv polymer yuav dhau qhov hla

- Kev faib cov ceev : Cov roj tog uas muaj RDP muaj cov ceev 32% tsawg dua nyob rau sab nraud ntawm qhov ploj siab

- Kev txhim kho qhov chaw hluas : Ib qhov dosage RDP 5% yuav txo qhov ntev ntawm qhov chaw hluas los ntawm 60%, pab ntxiv qhov tshuab kom tsis ploj siab

Qhov ntau thiab kev tiv thaiv qhov ploj siab hauv cov roj tog muaj polymer

RDP txiav mus rau kev puas tsuaj ntawm mortar los ntawm siv duab ntxoov mus rau duab hla, thaum kawg tseem sau ua zog tshav teeb. Kev ua haujlwm zoo tshaj plaws tau rau nrog 2.5–3.5% RDP:

| Kev ua | Mortar Ntawv Qeeg | Mortar Rau RDP Sau | Kev Txhim Kho |

|---|---|---|---|

| Zog Txeeb (MPa) | 4.2–5.1 | 6.8–8.3 | 63% |

| Roob ntsiab (Mpa) | 1.4–1.8 | 2.9–3.5 | 107% |

| Sau Saum Kab Ncaws Ncav | 0.1 mm | 0.4 mm | 300% |

Qhov duab polymer tsim khoob tso caij rau kab ncaws ncav, xav tau zog tshaj li plaub zaug dua kom kab ncaws ncav tuaj ntau dua li nyob rau hauv qhov system uas tsis muaj sau.

Sib Thooj Zog Tshaj Li Zog Hla Nyob Rau Hauv Qhov Sau Tsheb Siv Ntawm Xa Mus

Kev Sau Tsheb Ntshiab Tuaj Yeem Nrhiav Tau Qhov Zoo Tshaj Plaws Los Sib Thooj Ntawm Zog Tshaj Li Zog Hla Los ntawm:

- Kev xa tawm RDP : 2–3% rau sab ntim, 4–5% rau sab nrauj uas xav tau kev tiv thaiv tsis hlo tshaj

- Cov kev lag luam sib txuas fiber-RDP : Sib chaws 1.5% RDP nrog 0.2% cov sib fiber polypropylene tuaj yeem ntxiv zog tso tawm los ntawm 200%

- Kev txhim kho los ntawm nanoparticle : Ntxig 0.5% nano-SiO₂ nrog RDP tuaj yeem ntxiv zog hauv pem teb los ntawm 40% thiab tsis txhob hlav kev ua kom yooj yim

Kev nyiam loj thiab Kev Tshawb Nrhiav Thaum Deem Ntev ntawm Cov Mortar RDP-Hloov

Kev tiv thaiv tso tawm rau kev rov qab los ntawm kub thiab kev nyiam ntawm qhov ntev

Tus mortar uas tau siv RDP kho tshwm sim li 30% zoo dua nyob rau hauv kev tsim kheeb ntsim thaum muaj kev npog rau sab nraud txiav rau lub caij ntuj sov dua rau cov duab yooj yim, raws li tus neeg kho mob tshuaj lom neeg taw qhia los ntawm 2023. Qhov polymer component no feem ntau nyob ib leeg absorb cov zog ntawm kev rooj siab thiab kev ncaws siab, txav mus rau 40% tshaj qhov chaw uas sib txawv about 40 degrees Celsius thaum plua plav. Qhov kev ua kom yooj yim no pab tiv thaiv kev tsim cov ntxhiag ntxhib los ntawm kev npog thiab ncaws sab nraud, uas ua rau cov khoom no zoo tshaj rau kev tsim kho tsev uas tau raug npog ntau tshaj plua plav.

Kev tiv thaiv dej thiab kev nyob zoo thaum dej ncaws thiab thawj tshwm sim los ntawm RDP

Kev tsim kho tshuab qhia tias tsev hniav ntawm RDP tau dhau 98% kev tiv thaiv rwb xwv nyob rau hauv EN 1015-18, zoo dua tshuab ntau dua 22 feem pua. Lub polymer film txuas mus rau lub sijhawm peev xwm rwb xwv nyav mus rau ≤0.5 kg/m²·h thaum twb muaj kev tiv thaiv kev sib npaug. Tom qab 50 zaug ntawm kev sib txawv khib thiab thawj raws li ASTM C666, tsev hniav tau tsim kho tau nyob ib leeg 75% ntawm nws tus nuj nqaij tshuab dhau los.

Kev Siv Ntev Thiab Kev Tshawb Nrhiav Nyob Rau Hauv Qhov Chaw Nyuaj

Thaum tshuaj xyuas cov ntaub ntawv nyob ze rau qhov chaw nyob ze saum toj, peb pom tias RDP hloov kho tau siv tau ib txoj kev nyiaj loj txaus li 0.8 MPa tom qhov chaw nyob ib puag ncig thiab tia UV tu si tsis tag 15 xyli. Qhov yooj yim uas txawv ntawm cov khoom no yog polymer reinforcement uas pab sov dua qhov kev phom sij. Thaum sim nyob rau hauv qhov chaw uas sim li 30 xyli, cov khoom no muaj qhov nyiaj loj dua li 60% kom compared to standard products. Thiab tsis txhob kaw lus txog qhov chaw nyob saum togav. Cov mortar uas tsim los ntawm cov technology no tsuas muaj qhov sib txawv tsawg dua li 5% rau kev tiv thaiv kab ntsug sau los ua ib xyli.

RDP Dosage Zoo Tshaj Plaws thiab Kev Siv Nyob Rau Hauv Cov Chaw Tso Kho Nyob Tam Sim No

RDP Dosage Thov Xav Tau Rau Txhua Hom Qhov Chaw thiab Qhov Chaw Muaj Nuj Nqi

Ntau tus kws tshuaj txhawj xeeb nug siv RDP nyob rau hauv qhov ntau li 1% mus rau 5% ntawm qhov loj ntawm mortar, nyob ntawm dab tsi qhov chaw nyob cuaj rau nws thiab yog tias cov kauv yuav tsum ua li cas. Cov neeg tsim kauv nyob ze puag ncig dej muaj zog feem ntau siv li 3-4% vim lawv tab tom sim rau ib txoj kab ntsug khaub npag uas tsim hauv mortar. Nyob rau qhov chaw poob plaws uas feem ntau hlawv thaum muaj dej, cov neeg tsim kauv feem ntau siv li 2-3%. Rau cov tog raj kheej siab uas pheej rau ruaj tshab ntau, feem ntau yuav tsum tau siv li 4-5% vim qhov no pab rau vaj khoom kom zoo siab dua thiab nyob ntev dua. Tab sis tsis txhob siv ntau dua 5%. Ib qhov kev test dhau los piav tias siv ntau dua RDP tuaj yeem txhankhov kev sib xyaw thiab txav koj qhov ceev theej hnyav ntawm mortar, uas tsis muaj leej twg xav tau thaum lawv xav kom finished lub project raws li calender.

Kev siv rau Thermal Insulation thiab Anti-Crack Mortars, Piv txwv ETICS

RDP muaj feem tshaj tawm hauv kev sib cuag sib chig sib txuas thiab sib poob ntawm qhov chaw siv siab (ETICS) vim nws pab txhim kho qhov tshwm sim ntawm cov khoom siv rau ib puag ncig polystyrene. Cov kev soj ntsuam pom tias muaj txoj hlua siab dua li cov mortar tsis muaj kev hloov pauv nyob rau hauv qhov chaw ntau npaum li 40%. Thaum siv nrog rau kev tsim cov siv rau kev tswj xyuas kev hloov chaw ntawm substrate, RDP pab cov mortar tswj xyuas kev hloov chaw ntau heev txog 0.3 mm ua ntej muaj kev ruaj. Cov ntsiab lus uas pom los ntawm qhov chaw tsim kho nyob hauv cheeb tsam uas muaj kev ntxoov ntxooj tuaj yeem pom tias muaj yam ntxiv zoo. Cov tsev uas siv cov RDP pab txhim kho qhov sib poob meej meej tau pom tias muaj kev ruaj tsawg dua li 60% thaum muaj kev ntxoov ntxooj ntau yam tom qab kev ntxoov ntxooj loj. Qhov tshwm sim no yeej muaj feem tshaj tawm hauv cheeb tsam uas kev ruaj ntseg ntawm qhov chaw yog yam tseem ceeb tshaj plaws.

Sib piv nyiaj, tshwm sim, thiab kev nyob dai hauv kev xaiv cov khoom ntxiv

Kev kawm xyuas txog daim ntawv tsim kho tshuaj suggest tias nyob rau hauv qhov chaw li 2.5 mus rau 3.5 feem RDP yog qhov raug tshwj xeej tshwj plaws tshwj siab tshwj nqi thiab kev ua haujlwm. Qhov kev siv no tuaj yeem tso caij nqi tshuaj khoom nyob rau qhov tseem ceeb li €120 mus rau €180 saum ib pa, thaum twg kuj tseem txaus siab tias muaj kev nyob ntev zoo. Thaum cov chaw tsim khoom mus saum qhov threshold no, piv txwv li saum 2%, lawv tau nyiag siab ntau dua, nyiaj cuv li €50 mus rau €70 tsawg dua saum ib pa. Tab sis muaj ib qhov xwm txheej. Cov nqi tsuag tsawg no nyuaj siab tshaj plaws tias yuav tsum tau kho dua, tshpecially nyob rau qhov chaw uas mntang sov thiab mntang tsha tsha, txeem tshaj 35%. Kev xav txog dej nkhaus tag nrho tau los ua rooj teeb meem ntau dua nyob rau hauv qhov chaw RDP tau raug siv. Cov khoom siv uas muaj 30% khoom siv roj teem tau los siv dua tau muaj neeg nyob ntau dua thaum twg kuj muaj qhov sib txawv leej twg li ntawm cov khoom siv tshaiv. Lawv tseem tuaj yeem ua haujlwm li 90% zoo li cov khoom siv tshaiv, tab sis kom tsawg dej nkhaus CO2 tas li 1.2 kilograms rau ib pa mortar uas tsim.

Cov lus nug tshaj tawm txog RDP nyob rau hauv kev tsim kho

RDP siv los ua li cas nyob rau hauv kev tsim kho?

RDP siv los pab txhim kho cov ntawv qhia ntawm cov mortar tsim kho, xws li kev nyuaj siab, kev muaj zog, kev tso tawm dej, thiab kev nyob ntev. Nws tseem muaj cuab yeej tshaj rau kev pab ntxig rau Exterior Insulation and Finish Systems (EIFS) thiab los kom saus tsawg dua.

RDP ua li cas pab ntxig kev nyuaj siab ntawm mortar?

RDP pab ntxig kev nyuaj siab los ntawm kev tsim ib lub film polymer thaum nws tag, uas tsim ib qhov nyuaj siab hauv sab hauv rau ntau yam khoom siv xws li concrete thiab lub vij tog.

Cov nqi siv RDP feem ntau yog dab tsi rau ntau yam kev siv nyob rau hauv kev tsim kho?

Cov nqi siv RDP feem ntau nyob ntawm 1% mus rau 5% ntawm tag nrho qhov loj ntawm mortar, nyob ntawm kev sib txawv kawg thiab cov nyhuv meej meej ntawm daim tsim kho.

RDP ua li cas pab ntxig kev tawm saus?

RDP txo cov khaub ncaws tshwm sim los ntawm kev tsim kho lub network polymer uas faib tiv thaiv zog thiab txo lub teeb meem tshwm sim, yog li ntawd txhim kho qhov kev ua lej nyob hauv qhov chaw nyob hauv qhov chaw.

Daim Ntawv Qhia

- RDP yog dab tsi thiab nws ua haujlwm li cas hauv dej nkhis tshuab?

- Txhawb kev nyeej: RDP ua li cas txhim kho kev nyeej ntawm mortar thiab substrate

- Txhim kho kev tiv thaiv kab ntsug thiab qhov siab thaiv tom qab sib zog nrog RDP

- Kev nyiam loj thiab Kev Tshawb Nrhiav Thaum Deem Ntev ntawm Cov Mortar RDP-Hloov

- RDP Dosage Zoo Tshaj Plaws thiab Kev Siv Nyob Rau Hauv Cov Chaw Tso Kho Nyob Tam Sim No

- Cov lus nug tshaj tawm txog RDP nyob rau hauv kev tsim kho