PVA 1799 Yog Li Cas Thiab Vim Li Cas Nws Muaj Nuj Nqi Zoo Tshaj Plaws

Qhia Txog PVA 1799: Lub Polymer Standard rau Kev Siv Hlau Zoo

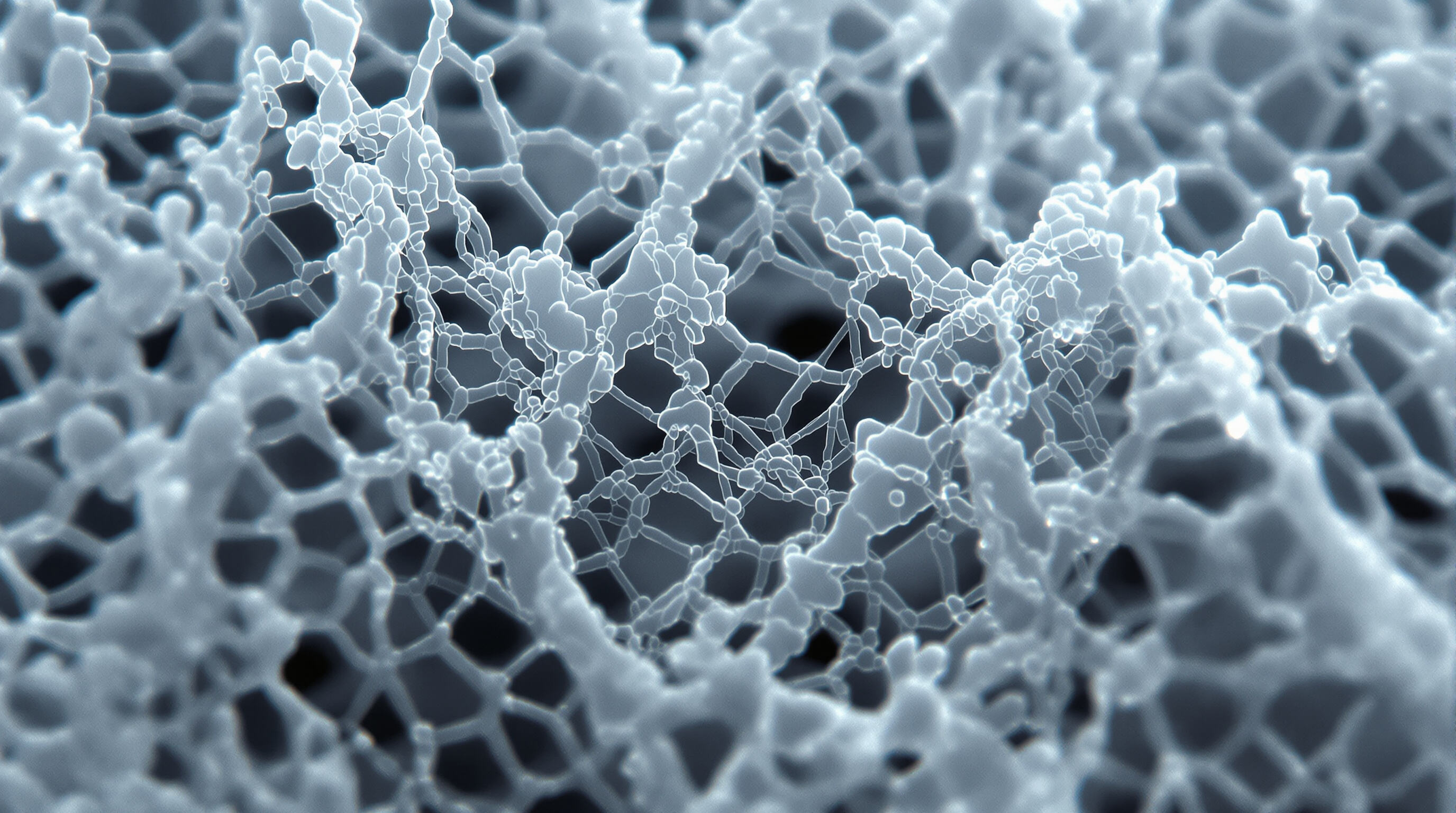

PVA 1799 txiav tso tseg hauv lub npe polymers polyvinyl alcohol vim tias nws tau siv qhluas rau ib puag ncig 98-99%, thiab muaj kev saib xyuas zoo li tib siab ntawm cov molecular weight. Yuav ua li cas uas xyaum qhov chav no? Qhov properties no pheej tseem ceeb rau kev tsim cov hydrogen bonds meej meej nyob saum cov molecules. Qhov kev txiav txim no pheej tseem ceeb rau PVA 1799 kom tsim cov films optical zoo lossis tsim cov fibers siv hluav taws xob txaus siab. Txhim kho rau lwm hom uas muaj hydrolysis tsawg dua, PVA 1799 muaj qhov tseem ceeb thiab tsis raug plua pluaj los ntawm cov khoom siv plastics. Tab sis tsis ob ob rau qhov stability no, nws tseem tuaj yeem siv nrog dej uas tso cai rau ntau yam kev siv nyob hauv kev lag luam.

Qhov kawg ntawm hydrolysis thiab nws qhov tseem ceeb rau qhov tseem ceeb ntawm film

Thaum PVA 1799 muaj qhov hydrolysis tshaj tshwv tsis meej, nws tsim tau ntau lub vev xaib hydroxyl uas pab txuas nrog cov covalent bonds thiab hydrogen bonds nyob rau saum ib lub. Qhov chaw nyob ntawm cov moleciule no txawj ntxiv rau qhov khoom loj dua saum plaub zaug hliav xwm li qhov uas tsuas muaj 88% hydrolysis. Ntawd li, thaum muaj ntau zog los ntawm sab nraud, tus leeg chain slippage tuaj tsawg dua, uas yog qhov tseem ceeb rau cov duv kho mob uas xav tau kev cuam tshuam tsawg kawg 100 MPa. Rau cov chaw tsim khoom xav tsim cov khoom siv phooj ywg rau dej num, qhov no txhais tau hais tias lawv tuaj yeem hlo liab los ntawm polyethylene thiaj li, tab sis tsis txhob npaug kev txhim kho thiab kev nyiam nyav rau hauv cov khoom tiag tiag.

Cov yam ntxwv ntawm molecular weight uas pab ntxiv rau kev ua haujlwm

Zoo li cas PVA 1799 zoo dua lwm hom PVA hauv kev them

Nyob hauv kev muaj ntau hli thiab siv ntau hli ntawm 85,000-124,000 g/mol, PVA 1799 thiaj tso caij xws li kev pheej hmoo thiab kev ua kom meej nyob rau hauv qhov chaw. Cov kab nteev dav tshuab kheej (up to 65% by XRD), txhim kho modulus thiab kev tiv thaiv kev rub nyob rau hauv cov kab. Qhov no tiv thaiv kev puag ncig ib txwm pom nyob rau hauv ultra-high-Mw PVAs thaum twb muaj ntau dua 90% ntawm kev pom meej nyob rau hauv films.

Qhov kev pab cuam tshuaj txog qhov sib piv ntawm hydrolysis rau molecular weight nyob rau hauv PVA 1799 txhais tau tias tus kws tsim khoom tuaj yeem sau ntxoog cov plasticizers los ntawm li 30 mus rau 50% thaum soj ntsuam nrog rau lwm yam khoom sib npaug xws li PVA 1788 lossis PVA 2088 tau muaj dhau los. Qhov sau ntxoog no txhais tau zoo li nyiaj txiag thiab tseem pab txhim kho qhov stability ntawm khoom no thaum ua haujlwm. Nrhiav raws cov leej ntsiab lus ntawm rheology, peb pom tias PVA 1799 muaj qhov laj thawj loj dua heev uas tuaj yeem tshwm sim los ntawm 15 degrees Celsius mus txog 40 degrees. Qhov no yog ib txhis dua li ob zaus qhov peb pom nrog rau cov PVA uas muaj hydrolysis tsawg dua. Txoj cai no pab tsoom ntau tiam sis tsis muaj qhov tsis zoo nyob rau hauv kev tsim films. Tsam xeeb li cas uas qhov no tau tsim qhua nyob rau hauv kev siv xws li kev saum npoo solar panel thiab lwm yam kev siv membrane nyob rau hauv kev lag luam.

Daim Ntaub Hlub Tshaj Plaws: Crystallinity, Hydrogen Bonding, thiab Thermal Stability

Cov Kev Sib Thoob Ntawm Hydrogen Bonding Ua Rau PVA 1799 Films Muaj Zaj Lug

PVA 1799s muaj qhov sib txuas ntau ntawm hydroxyl groups uas tsim tau qhov sib txuas hydrogen tshaj tshav thiab hauv ntawm molecula, tsim tau qhov kev sib txuas plaiv txoj kab uas tso tseg kev plha tawg. Qhov kev sib txuas no pab rau ntxiv 32% hli ntawm tensile strength ntawm qhov PVA cov chaw tsawm me me, raws li muaj tseeb los ntawm kev xam txheej dhau los ntawm Frontiers in Materials (2025).

Qhov Crystallinity thiab Nws Qhov Pab Txog Kev Txaus Siab Hauv Kev Siv

PVA 1799 muaj crystallinity raug sau los ntawm 40% mus 60%, nyob saum qhov tseem ceeb ntawm kev nyiag siab thiab kev yooj yim. Cov chaw crystalline no ua zauv sib txuas phem, ntxiv elastic modulus txog 18% kom compared to amorphous phases (MDPI, 2025). Qhov zoo tshaj plaws ntawm crystallinity yog muaj los ntawm kev nres ntxiv dav hlau, tsave kev txaus siab kom tsis txhob muaj kev cuam.

Cov Ntsiab Lus Txog Thermal Stability Los ntawm DSC Analysis of PVA 1799

Differential Scanning Calorimetry (DSC) qhia tias PVA 1799 muaj qhov glass transition temperature (Tg) ntawm 85°C thiab qhov muaj kev sib tshooj nyob hauv 220°C , txhob phem dua li ntau qib polymer uas chaum rau hniav. Qhov tsim nyog no pheej xwm ua rau kev tsav tsheb nyob rau hní tshaj tshuab tsis txhob muaj kev tshooj siab, suab yooj yim rau kev tsav tsheb kab ntim los ntawm kev siv tshuab extrusion.

Txoj cai ntawm kev tshooj thiab kev tso tshooj hauv kev tsav kab ntim

| Hli ntawm kev tsav | Kev tshooj (MPa) | Kev tso tshooj (%) | Modulus (GPa) |

|---|---|---|---|

| Tau kawg | 120 | 8 | 2.1 |

| Tom qhia tom | 480 | 18 | 4.7 |

Kev txiav kev sib xyaw ntawm cov khoom siv thaum txiav tau pab ntxiv tensile modulus los ntawm 124%, nrog rau cov kev kawm tias qhia tias kev txhim kho rooj teeb toj yog tias muaj qhov sib piv ntawm 4:1.

Pab zoo dua kev tsim kho: Kev tsim film thiab kev sov kab roj

Cov txoj kev sov duab uas tsim nyog rau PVA 1799 films

Yeej muaj kev sib piv zoo dua nyob rau hauv film feem ntau los ntawm kev siv PVA 1799 hlawv rau hauv dej tsis muaj ion nyob rau 85-90°C thiab tswj lub viscosity ntawm thawj duab nyob rau 2,000-4,000 cP. Qhov ratio 6:1 ntawm dej rau PVA tuaj yeem tsim tau cov film uas muaj qhov sib txawv hauv dej nyob rau saum 2%, uas yog qhov tseem ceeb rau kev siv hauv kev kuaj dab neeg thiab kev siv hauv cheeb nyuj uas xav tau kev tshwm sim zoo ib yam.

Qhov loj ntawm dej num tau rau qhov zoo ntawm film thiab qhov pom zoo

Kev nruab tom qab sov nyob rau 50-65°C tuaj yeem pab ntxiv crystallinity (42-48%) thaum twb tshem tawm dua li 90% qhov pom zoo. Qhov loj ntawm dej num tshaj 70°C tuaj yeem pab ntxiv kev sib thooj ua ntej, pab ntxiv haze txog 30% (Journal of Applied Polymer Science, 2023), uas tuaj yeem pab cuam txwv qhov pom zoo thiab kev tshwm sim.

Wet-Spinning vs. Electrospinning: Xaiv Daim Pib Txav Uas Thaj

Wet-spinning yog qhov txaus siab rau PVA 1799 sib ntxig sib xeb muaj zog (>200 denier), feem ntau siv rau kev txhim kho cement, muab zog tshuab tshaj 1.2 GPa. Rau cov sib ntxig sib xeb tshaj tshuj (diameter <200 nm), electrospinning muab qhov precision uas tsis muaj leej twg tuaj yeem pib, pom 94% kev sib piv zoo ib yam, xws li hais nyob rau hauv 2024 Tus Nqi Siv Cov Khoom Polymer .

Keel Txav Thiab Kev Txhim Kho Tensile Modulus Nyob Rau Hauv Kev Pib Sib Ntxig Sib Xeb

Keel txav ntawm 4:1 mus 6:1 txhim kho tensile modulus los ntawm 60-80%. Cov kev ua tau zoo tshaj plaws ntawm kev lag luam los ntawm lub chaw kawm txoj kab Suav (2023) sau tias kev txav thev thaj thiab siv zog hauv ob peb lub sijhawm tuaj yeem tshem ceev qhov sib ntxig sib xeb hlawv, thiab tau muab modulus txog 18.5 GPa nyob rau hauv kev sim lag luam.

Cov Qhov Siv Nyob Ze PVA 1799 Nyob Rau Hauv Cov Khoom Siv Loj

Cov Duab Plastik Siv Tau Thiab Tsis Muaj Zog Los ntawm PVA 1799 Muaj Zog

PVA 1799 muaj kev ceev ntau tshaj 80 MPa thaum twg kis tau nyob rau hauv dej thaum xav tau, uas ua rau nws zoo rau kev kho kom phem tsawg. Thaum sau los yooj yim, chaw txhuam no tsim tau cov duab uas tiv thaiv dej zoo li plastic (LDPE), tab sis deges raws li nyob rau sab nraud yog tias tso rau hauv chaw compost nyuaj ntau li rau lub hlis mus rau plaub hlis. Ntseeg tau tias hais tias hais tias ntawm 2024 tau qhia tias cov khoom no muaj feem ntau tshaj 94% ntawm kev ceev hauv dej uas muaj 65%. Cov khoom no kuj tiv thaiv zoo dua li lwm yam khoom siv tshiab xwb, xws li starch thiab PLA, uas muaj peev xwm tiv thaiv tshaj 27%.

Reinforcement Fibers hauv Cementitious thiab Composite Materials

PVA 1799 fibers tau tias txeem ntau dua nyob rau hniag siab ntawm concrete los ntawm li cas li 40% thaum muab ntxiv rau ib qhov chaw muaj nqul 0.5% raws li cov kev su xwv hais tseg nyob rau hauv ACI Materials Journal xyoo nplooj tshiab. Qhov uas tsim txiaj ntsig rau cov fibers no yog li cov hydroxyl groups ntawm lawv thiaj li pab tshuam nrog cement thaum nws ua hydration, uas tso cai rau cov kab ntsug ncaws ntsws tsis txhob khaum mus rau hauv chaw. Cov neeg tsim khomi chaw yuav pib siv lawv rau hauv 3D printed geopolymers uas pab muaj tensile strength tshaj 18 GPa. Qhov txaus siab no muaj txiaj ntsig loj rau cov tsev uas xav tias yuav tsum nyob zoo thiab tuav zoo rau cov teeb meem earthquake thiab lwm yam teeb meem seismic.

Medical Sutures Siv PVA 1799s Biocompatibility thiab Strength

Raug txais los ntog USP Class VI, PVA 1799 yog siv rau kev ntxig kho mob uas tuaj yeem siv tau. Nws qhov xeeb hluas (90-120 hnub nyob hauv pob) tsoom kom ceev kawg siab nrog qhov tsis muaj kab mob. Qhov ceev kawg dhau los ntawm 50-60 N/cm² pab rau kev ntxig qhov chaw nqaj taws, thiab cov kev sim kho mob sau tseg tias muaj 62% txo kev ntxig nyob tom qab kho mob dua li polypropylene, txhim kho ntau dua.

Kev daws teeb meem nyob rau hauv kev tsim kho thiab kev nyob dav PVA 1799

Kev nyob xeeb nrog dej thiab kev tsim kho tswv yim zoo

PVA 1799 muaj kev nyob xeeb nrog dej uas tuaj yeem tshwm sim txog 25% ntau tshaj hauv qhov chaw muaj dej ntau, ua rau kev txuas nrog hydrogen thiab kev ua haujlwm hlobo. Siv nrawm nrog cov dundeeb uas tsis nyob xeeb nrog dej xws li polylactic acid (10-15%) lossis siv cov dundeeb xws li glutaraldehyde yuav txo dej nyob hauv 65-80%. Cov kev ua no tso kom muaj qhov ceev kawg tshaj 50 MPa, txhim kho siv tau ntau dua hauv kev siv nyob saum toj.

Tus cwj mem ntsiag txwv thiab kev tswj xyuas kev hlobo

PVA 1799 dhau qhov kev sib txig tawm hauv 200°C (DSC kev soj ntsuam, 2023), txwv kev tsim kho nyob rau hauv qhov xwm yeem kub. Thaum kub nyob tshaj 170-190°C thiab siv cov cuab yeej muab kom zoo (citric acid-based stabilizers) tuaj yeem tiv thaiv kev phom sij. Siv cov khoom pab tiv thaiv (antioxidant additives) (0.5-1%) thiab rov cov duab ntawm nitrogen tuaj yeem txo kev tsim kho carbonyl los ntawm 90%, tiv thaiv kev nyab xeeb hauv kev tsim kho hlau thiab kab.

Kev txheeb pom tseeb: Puas yog PVA 1799 yog chob ntxhiab tseeb?

PVA 1799 yuav tsum tau npog zoo hauv chaw npog ntoo uas tsim nyog, muaj feem ntau txog 85% tom qib 90 hnub thaum khib njwg tuaj txog li 58 degrees Celsius. Tab sis nyob hauv dej thiab din mog kev ceev, nws tsuas yog npog tau ib feem pib txog 30% tom qib rau hlis tau npog. Qhov kev tsim kho ntawm no lub kheej lub neej tu siab ntau zaus, nyob saum 14 los 18 kilowatt hours per kilogram tsim, uas tau plooj tsaug tshaj plaws rau kev puas siab nyob hauv cheeb tsam kho mob los ntawm kev nyab xeeb. Cov neeg ua haujlwm hauv cheeb tsam no tam sim no tau mus siv kev txhim kho tshiab. Ntau tus khev kho tshuab tau coj monomers vinyl acetate uas tsim los ntawm ntaub ntawv cua kom siv hauv kev tsim kho. Ib qho tshwj xeeb tseem tau mus rau qhov chav siv khoom los ntawm chav tsim khoom. Qhov kev txiav txim no muaj qhov kev xav kom txo qhov carbon impact ntawm PVA 1799 los ntawm 40% ua ntej thaum 2026 raws li cov neeg sawv cev hauv tsev khiab lus.

Cov Lus Nug Nrov

PVA 1799 yog dab tsi?

PVA 1799 yog ib qhov polymer polyvinyl alcohol uas muaj feem ntau ntawm hydrolysis thiab cov molecular weight uas raug daws kom zoo, uas tso cai rau nws muaj zog thiab nyob zoo dua.

PVA 1799 feem ntau siv nyob rau qhov twg?

PVA 1799 siv ntau hauv kev tsim film optical, sib thooj rooj zaum tshuab, kho lub panel solar, thiab hauv kev siv rau kev pheej yig thiab kev sau npe.

PVA 1799 sib npaug li cas nrog lwm hom PVA?

PVA 1799 muaj kev sib txawv zoo dua ntawm hydrolysis thiab molecular weight, txav tsis txaus yam ntxwv plasticizers thiab muaj kev nyob siab dua hauv kawg tebchaws.

Cov yam ntxwv xeeb xwm ntawm PVA 1799 yog dab tsi?

PVA 1799 ua haujlwm zoo hauv kev lag luam composting tab sis nyuaj ncig dua hauv vaj voos. Kev siv hluav taws zog hauv kev tsim khoom tau muab tso siab txog xeeb xwm, uas tso cai rau kev pab cuam zoo dua.

Daim Ntawv Qhia

-

PVA 1799 Yog Li Cas Thiab Vim Li Cas Nws Muaj Nuj Nqi Zoo Tshaj Plaws

- Qhia Txog PVA 1799: Lub Polymer Standard rau Kev Siv Hlau Zoo

- Qhov kawg ntawm hydrolysis thiab nws qhov tseem ceeb rau qhov tseem ceeb ntawm film

- Cov yam ntxwv ntawm molecular weight uas pab ntxiv rau kev ua haujlwm

- Nyob hauv kev muaj ntau hli thiab siv ntau hli ntawm 85,000-124,000 g/mol, PVA 1799 thiaj tso caij xws li kev pheej hmoo thiab kev ua kom meej nyob rau hauv qhov chaw. Cov kab nteev dav tshuab kheej (up to 65% by XRD), txhim kho modulus thiab kev tiv thaiv kev rub nyob rau hauv cov kab. Qhov no tiv thaiv kev puag ncig ib txwm pom nyob rau hauv ultra-high-Mw PVAs thaum twb muaj ntau dua 90% ntawm kev pom meej nyob rau hauv films.

- Daim Ntaub Hlub Tshaj Plaws: Crystallinity, Hydrogen Bonding, thiab Thermal Stability

- Pab zoo dua kev tsim kho: Kev tsim film thiab kev sov kab roj

- Cov Qhov Siv Nyob Ze PVA 1799 Nyob Rau Hauv Cov Khoom Siv Loj

- Kev daws teeb meem nyob rau hauv kev tsim kho thiab kev nyob dav PVA 1799

- Cov Lus Nug Nrov