Biomass VAE

Description

Overview

VAE emulsion is the abbreviation of vinyl acetate-ethylene copolymer emulsion, which is produced by medium pressure emulsion polymerization with vinyl acetate monomer and ethylene monomer as basic raw materials.

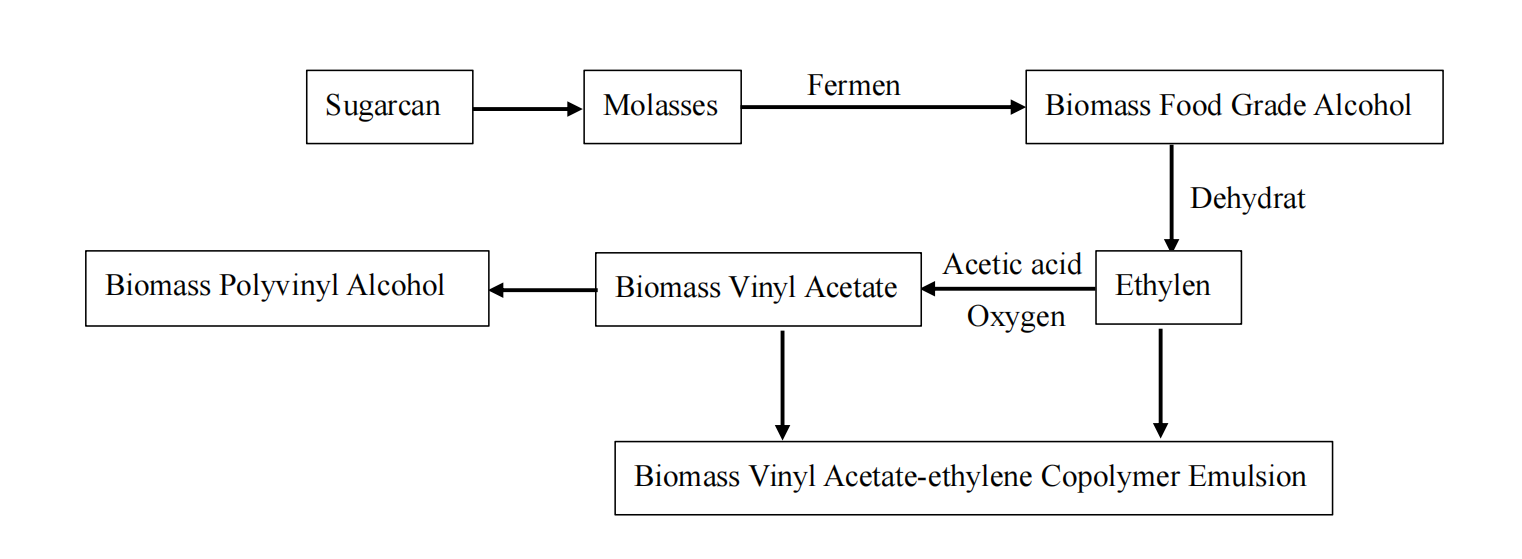

Technological process

Product quality index

Item |

Nonvolatile %≥ |

pH |

Viscosity(25℃)/mPa.s |

Residual vinyl acetate %≤ |

Dilution stability %≤ |

Minimum film forming temperature℃≤ |

Ethylene content %≤ |

GW-705 |

54.5 |

4.0-6.5 |

1500-2500 |

0.5 |

3.5 |

0 |

14-18 |

GW-705A |

50.0 |

4.0-6.5 |

1500-2500 |

0.5 |

3.5 |

0 |

14-18 |

GW-705SG |

54.5 |

4.0-6.5 |

1500-2500 |

0.5 |

3.5 |

0 |

14-18 |

GW-705HV |

54.5 |

4.0-6.5 |

2600-3100 |

0.5 |

3.5 |

0 |

15-18 |

GW-705 (low formaldehyde) |

54.5 |

4.0-6.5 |

1500-2500 |

0.5 |

3.5 |

0 |

14-18 |

GW-706L |

54.5 |

4.0-6.5 |

2500-3000 |

0.5 |

3.5 |

0 |

14-18 |

GW-706 |

54.5 |

4.0-6.5 |

3000-3500 |

0.5 |

3.5 |

0 |

14-18 |

GW-706GN |

54.5 |

4.0-6.5 |

3500-5000 |

0.5 |

3.5 |

0 |

14-18 |

GW-707 |

54.5 |

4.0-6.5 |

500-1000 |

0.5 |

5.0 |

0 |

14-18 |

GW-707N |

54.5 |

4.0-6.5 |

500-1000 |

0.5 |

5.0 |

0 |

14-18 |

GW-707A |

50.0 |

4.0-6.5 |

500-1000 |

0.5 |

5.0 |

0 |

14-18 |

GW-707L |

54.8 |

4.0-6.5 |

1000-2000 |

0.5 |

5.0 |

0 |

14-18 |

GW-907 |

54.5 |

4.0-6.5 |

500-1000 |

0.5 |

5.0 |

0 |

14-18 |

GW-707H |

54.5 |

4.0-6.5 |

1000-1500 |

0.5 |

5.0 |

0 |

14-18 |

GW-707H (low formaldehyde) |

54.5 |

4.0-6.5 |

1000-1500 |

0.5 |

5.0 |

0 |

14-18 |

GW-707 (low formaldehyde) |

54.5 |

4.0-6.5 |

500-1000 |

0.5 |

5.0 |

0 |

14-18 |

GW-102 |

55.0 |

4.0-6.5 |

3500-4000 |

0.5 |

3.5 |

0 |

16-18 |

GW-102H |

55.0 |

4.0-6.5 |

4000-4500 |

0.5 |

3.5 |

0 |

16-18 |

GW-102HN |

55.0 |

4.0-6.5 |

4000-4500 |

0.5 |

3.5 |

0 |

16-18 |

GW-5000 |

55.0 |

4.0-6.5 |

4500-5000 |

0.5 |

3.5 |

0 |

16-18 |

GW-6001 |

54.5 |

4.0-6.5 |

1000-2500 |

0.5 |

3.5 |

7 |

9-11 |

GW-6001A |

54.5 |

3.5-6.5 |

700-2000 |

0.5 |

3.5 |

0 |

9-11 |

GW-600 |

60.0 |

4.0-6.5 |

1500-3000 |

0.5 |

3.5 |

0 |

16-18 |

GW-602 |

60.0 |

4.0-6.5 |

2500-4000 |

0.5 |

3.5 |

0 |

16-18 |

GW-9208 |

54.5 |

4.0-7.0 |

1000-2000 |

0.5 |

3.5 |

10 |

5-9 |

GW-70228 |

54.5 |

4.0-6.5 |

800-1000 |

0.5 |

3.5 |

0 |

14-18 |

Product Application

Adhesive Base

Polyvinyl alcohol in the adhesive base material has become a multi-scenario bonding solution through the three-in-one mechanism of "polar adhesion-film enhancement-chemical modification". Its core value lies in safety and environmental protection, broad-spectrum bonding, and easy modification, and it is especially suitable for cellulose substrates.

Coating Base

VAE emulsion has become an ideal base material for architectural coating, industrial protection and special functional coatings through its triple core mechanisms of internal plasticizing flexible network, low-temperature film formation and environmentally friendly low VOC. It has the characteristics of environmental friendliness, balanced performance and economy.

Paper Sizing and Paper Glazing

Polyvinyl alcohol can be used as a paper surface sizing agent and reinforcing agent to improve paper strength, smoothness and water resistance.

Cement Modifier

Adding polyvinyl alcohol improves crack resistance, bond strength and water resistance, extending the life of the building.

More Application

• Waterproof paint

• Adhesives in the textile field

• Emulsion varnish

• Carpet adhesive

• Concrete interface agent

• Cement modifiers

• Construction adhesives

• Wood adhesives

• Paper-based adhesive

• Printing binder

• Waterborne composite laminating adhesive