Biomass PVA

Description

Overview

Biomass Polyvinyl alcohol (PVA) is a non-toxic, odorless and easily degradable water-soluble polymer made from vinyl acetate by polymerization and alcoholysis. PVA aqueous solution has good film-forming, adhesion, emulsification. The formed film has excellent adhesion, solvent resistance, friction resistance and oxygen barrier properties, and has both hydrophilic and hydrophobic functional groups, so it has interfacial activity, and can be used as a protective colloid during polymer emulsification and suspension polymerization.

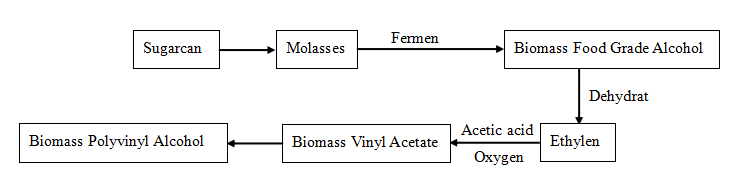

Technological process

Product quality index

Specification |

Item |

||||||||

Company standard |

Corresponding National Standards |

Degree of Alcoholysis/(mol/mol)% |

Average Degree of Polymerization |

Viscosity /mPa.s |

Volatile /%≤ |

Sodium Acetate /%≤ |

Ash /%≤ |

pH |

Purity /%≥ |

17-99(H) |

100-27H |

99.0-100.0 |

1600-1800 |

20.0-26.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

19-99(H) |

100-31H |

99.0-100.0 |

1800-2000 |

26.0-34.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

20-99(H) |

100-37H |

99.0-100.0 |

2000-2300 |

34.0-42.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

23-99(H) |

100-50H |

99.0-100.0 |

2300-2600 |

42.0-55.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

24-99(H) |

100-60H |

99.0-100.0 |

2600-2900 |

55.0-65.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

Product Application

Adhesive

Polyvinyl alcohol in adhesives has become a multi-scenario bonding solution through the three-in-one mechanism of "polar adhesion-film enhancement-chemical modification". Its core value lies in safety and environmental protection, broad-spectrum bonding, and easy modification, and it is especially suitable for cellulose substrates.

Coating

Polyvinyl alcohol has become a "performance bridge" in the coating system through the four mechanisms of film-forming reinforcement, interface bonding, construction optimization and functional modification. Its core value lies in the balance of rigidity and flexibility (improving the crack resistance and adhesion of the coating), water-air regulation (considering both waterproof and breathable requirements), and environmental protection and economy (non-toxic, biodegradable, and reducing the amount of emulsion). The selection needs to be combined with the application scenario.

Paper Processing

In paper processing, polyvinyl alcohol becomes a multifunctional additive that improves the comprehensive performance of paper through the three-in-one mechanism of "surface film formation-pigment bonding-fiber reinforcement". It has great advantages in terms of strength, printability, water resistance and environmental protection, and is especially irreplaceable in high-end paper and specialty paper.

Warp Yarn Sizing

Polyvinyl alcohol is used as a sizing agent to enhance yarn strength and abrasion resistance, reduce yarn breakage rate during weaving, and improve textile quality.