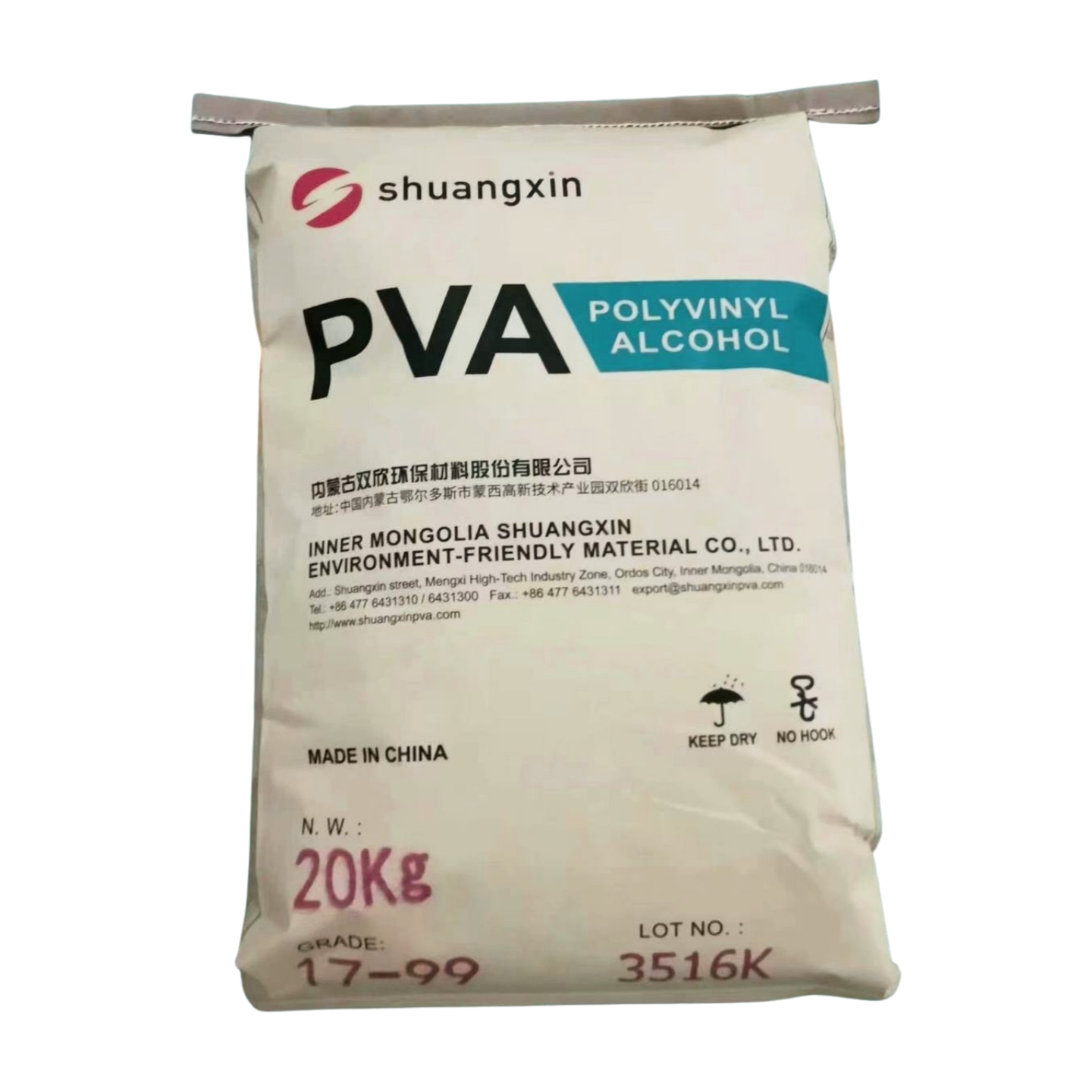

The Polyvinyl Alcohol adds value to the end product adhesives by strengthening the bond. The water-needy character of the polymer also facilitates mixing and application while the polymer forms film during the drying process adding strength and flexibility to the adhesive. Additionally, PVA offers the advantage of greatly enhancing adhesion when combined with other substances, thereby allowing industrial and consumer-grade products. This flexibility permits the manufacturers to cater to a wide range of customer base of various markets.