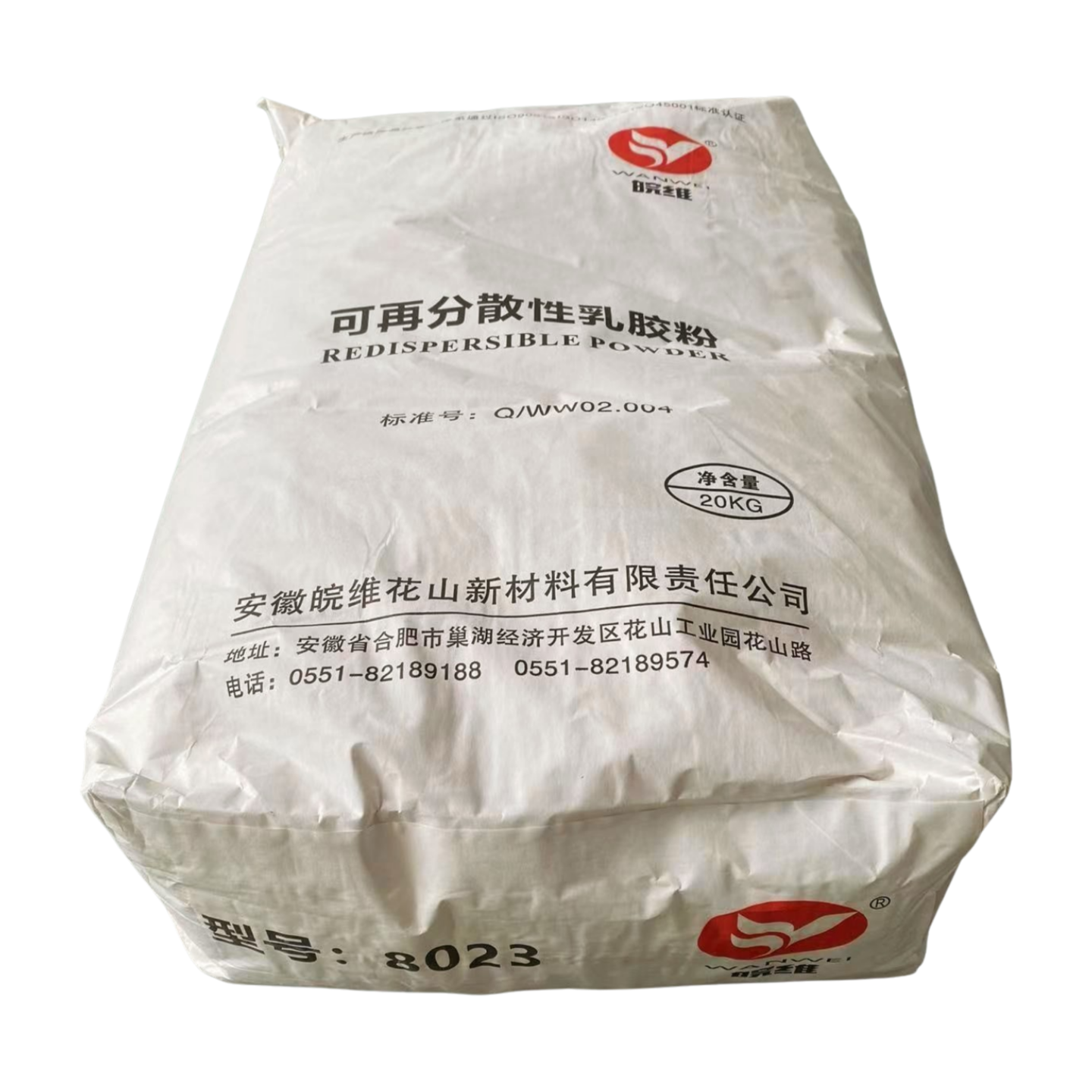

ຜົງໂພລີເມີ້ທີ່ສາມາດແຈກຢາຍຄືນໄດ້ ແມ່ນໂພລີເມີ້ທີ່ຖືກແຫ້ງດ້ວຍການພັ່ນຝຸ່ນ ເຊິ່ງຈະຖືກແຈກຢາຍອີກເທື່ອຫນຶ່ງເຂົ້າເປັນເອມັນຊັນທີ່ໝັ້ນຄົງໃນທັນທີທີ່ສຳຜັດກັບນ້ຳ. ທຳມະດາແລ້ວຈະອີງໃສ່ລະບົບ VAE, ມັນຊ່ວຍປັບປຸງການຍຶດຕິດ, ຄວາມຍືດຍຸ່ນ ແລະ ຄວາມຕ້ານທານນ້ຳໃນຜະລິດຕະພັນກໍ່ສ້າງທີ່ປະສົມແຫ້ງ. ການນຳໃຊ້ປະກອບມີກາວຕິດໄມ້ກະດານ, ລະບົບฉນວນທີ່ຕິດຕັ້ງດ້ານນອກ, ມໍດຕິດແປງ, ແລະ ສີກັ້ນນ້ຳ. ຮູບແບບຜົງຊ່ວຍໃຫ້ການເກັບຮັກສາ ແລະ ການຂົນສົ່ງງ່າຍຂຶ້ນ ໃນຂະນະທີ່ອະນຸຍາດໃຫ້ຄວບຄຸມປະລິມານຢ່າງແນ່ນອນ. ຫຼັງຈາກການແຈກຢາຍຄືນ, ມັນຈະຟື້ນຟູຄຸນສົມບັດການເຮັດວຽກຂອງເອມັນຊັນດັ້ງເດີມ. ສຳລັບຄຳແນະນຳໃນການປະສົມ ຫຼື ຂໍ້ມູນລາຄາ, ຜູ້ຊົມໃຊ້ຖືກສົ່ງເສີມໃຫ້ຕິດຕໍ່ໂດຍກົງ.