Biomass PVA

Piav qhia

Saib xyuas

Biomass Polyvinyl alcohol (PVA) yog peb nyob rau xav, tas los ntawv, thiab mus rau hais tias lub tsis muaj kev pab. PVA hom qhov ntsuas li cas yam, txiav, thiab emulsification. Lub film lis yog cas yam, solvent resistance, friction resistance thiab oxygen barrier properties, thiab yog ib tug hydrophilic thiab hydrophobic functional groups, ntawm nej yog interface activity, thiab yog mus rau hais tias peb yog protective colloid no yog mus rau polymer emulsification thiab suspension polymerization.

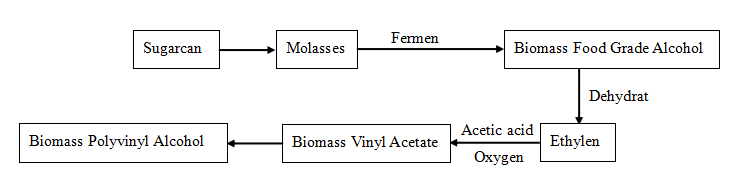

Txoj txheej txheem thev naus laus zis

Qib zoo ntawm cov khoom

Specification |

Khoom |

||||||||

C kompani standard |

Tsis txhawb N ation S standards |

Rooj ntsig ntawm Alcoholysis/ (mol/mol )% |

Tsis tsis los noj rooj polymerization |

Viscosity /mPa.s |

Volatile /% ≤ |

Sodium Acetate /% ≤ |

Tshauv /% ≤ |

pH |

Purity /% ≥ |

17-99(H) |

100-27H |

99.0-100.0 |

1600-1800 |

20.0-26.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

19-99(H) |

100-31H |

99.0-100.0 |

1800-2000 |

26.0-34.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

20-99(H) |

100-37H |

99.0-100.0 |

2000-2300 |

34.0-42.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

23-99(H) |

100-50H |

99.0-100.0 |

2300-2600 |

42.0-55.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

24-99(H) |

100-60H |

99.0-100.0 |

2600-2900 |

55.0-65.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

Tawv Tshaj Txhais

Cov txog xyoo

Alcohol Polyvinyl hauv kev ncaj ncees tuaj yeem ua raws li qhov kev pab tiv thaiv, sib txuas zoo thiab ua rau yooj yim dua. Nws cov nuj nqo ua haujlwm yog tiv thaiv kho mob, sib txuas zoo thiab ua rau yooj yim dua, thiab nws yog ib qho tsim nyog rau cellulose substrates.

Tsis lawm

Alcohol Polyvinyl tau ua rau muaj "kev nthuav dav" hauv cov roj ntxuav los ntawm 4 qhov: film-forming reinforcement, interface bonding, kev lag luam thiab kev kho tshuaj nrog. Qhov tseeb ntawm nws yog qhov zoo ua ke ntawm kev ceev thiab kev ua kom zoo (ua kom zoo dua qhov ua kom tsis txawv thiab sib txuas), kev ua kom haum (xav txog ob peb yam xaus thiab kev ua kom sov), thiab kev tiv thaiv kho mob thiab kev ua kom yooj yim (tsis lom neeg, ua kom raug, thiab khawm emulsion). Cov lej yuav tsum tau pom nrog lub sijhawm.

Processing Daim Ntawv

Nyog kev tsim kho ntawv, cov polyvinyl alcohol yog ib qho khoom siv zoo heev uas tuaj yeem pab huvav kom zoo dua thiab ua haujlwm zoo dua los ntawm kev ua nrog tib lub zog ntawm "qeeb pov ntawv-kev nyob rau hauv-sib txuas ntawv". Nws muaj peev xwm zoo heev hauv kev huvav, kev sau ntawv, kev tiv thaiv dej thiab kev saib xyuas pob ze, thiab tseem yog ib yam uas tsis muaj leej twg hnav tau hauv kev tsim kho ntawv zoo thiab ntawv ua haujlwm siab.

Kev Ncav Duab Pov

Polyvinyl alcohol raug siv los ntawm ib qho ua pov kom zoo dua kom pov zoo dua thiab kom tsis hnov mob, kom tsawg tus pov breaking hauv kev tsim kho, thiab pab kom zoo dua hauv kev tsim kho lwm yam.